Design & Mfg. Software

Engineering, Calculation and Reference Resource Software for Moldmaking

DZynSource for Molds software, version 3.0.0, has just been released.

Read MoreEarly Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

Read MoreAdvanced Toolpaths Improve Cutter Performance in Difficult Materials

Trochoidal toolpaths are available on most CAD/CAM systems, yet are rarely used or even known. By using trochoidal toolpaths and hybrid trochoidal toolpaths you can successfully machine exotic materials.

Read MoreCAD/CAM Package Improves Speed, Accuracy And Design Time for Complex Molds

This blow mold manufacturer finds a software package that is able to work with complex curves and surfaces quickly and efficiently.

Read MoreThe Many Dimensions of Feature-Based Machining

Simple does not mean minimal. FBM is a powerful tool that can save many different types of users’ time and money. Here’s why.

Read MorePost-Processor Pointers

In addition to the development of CAD/CAM software, it is important not to forget the importance of post-processors, which manage numerically controlled machines. Without the right post-processor the best CAD/CAM software is of no use; likewise, the most sophisticated machine will not function optimally without the right post-processor.

Read MoreHot Runner Justification

How OEMs, molders and moldmakers can better determine when it makes sense to use hot runner technology.

Read MoreDetecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

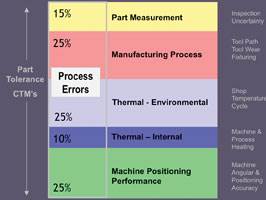

Read MoreAvoid Chasing CNC Variability with CAM

Moldmakers who produce tooling for medical devices and many other high precision molded products have been under increasingly greater pressure to reduce the variability of tooling components manufactured on their CNC equipment. One way they attempt to do this is by carefully adjusting offsets in the CAM program to compensate for variations in their equipment’s volumetric accuracy. Sometimes this works, other times not. Either way, the toolmaker pays a heavy penalty.

Read MoreDelving into Rapid Prototyping Technologies Attracts New Customers

Offering RP services and investing in technologies that help to constantly improve those services can help you reach potential new markets and allow your company to push the envelope of mold building technology.

Read More

.jpg;maxWidth=300;quality=90)