Design & Mfg. Software

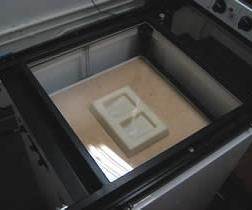

Printing Vacuum Forming Tooling with FDM

Combining the advantages of 3-D CAD and FDM technology, vacuum forming can be completed quickly, efficiently and cost effectively

Read MoreOptimizing Plastic Injection Mold Materials with FEA

Tooling cost reduction can be achieved with up-front engineering via company collaboration and simulation technologies based on finite element analysis.

Read MoreSoftware Suppliers Seek Common Platforms for Mold Development

The goal is efficient data transfer that significantly reduces mold build cycles and increases margins.

Read MoreThe Evolution of Process Training for Mold Builders

Process training coupled with cavity pressure data provides mold builders with value and information that can be passed onto customers.

Read MoreDSSP: The Catalyst for a New Revolution

One CAD short- coming—a frequent disconnect between the final manufactured product and the idealized CAD model—is being addressed with digital shape sampling and processing.

Read MoreComplex Molds Mean Business for High-Tech Toolmakers

Focus on cavitation and advanced product design gives progressive mold shops a jump on competitors.

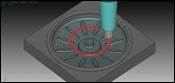

Read MoreCAM for Hard Milling

A brief overview of some of the CAM requirements, challenges and strategies for successful hard milling.

Read MoreValidation of Design Guidelines

Flow simulation software integrated with powerful 3-D CAD functionality can be effectively and efficiently applied to validate guidelines for cooling time and runner sizing.

Read MoreMoldmaker Uses a Solution-Based Approach To Mold Flow Analysis

MoldFlow consulting firm assists mold shop as it approached a complex molding program for its customer, Cessna Aircraft Company.

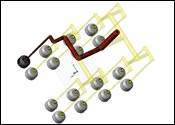

Read MoreMulti-Cavity Mold Issues Solved with Melt Rotation Process

Toolroom supervisor shares his experience with a rheological control solution to some obvious and some not-so-obvious challenges with product and color variations in a multi-cavity mold.

Read More

.jpg;maxWidth=300;quality=90)