Design & Mfg. Software

Perfecting the Moldmaking Process

One mold manufacturer’s secret to staying ahead: obtaining a full understanding of the entire molding process by cutting and shooting molds in their own shop, and investing in today’s machining technology to strengthen a niche in complex moldmaking.

Read MoreMeasuring CAD Skills Gives Greater Efficiency

CAD is at the heart of modern manufacturing and moldmaking. But just how good are people at using the CAD tools they are given? This article reviews the options for assessing the skills and training needs of CAD users.

Read MoreEquipment Expansion Lands Additional Customers

Adding equipment to the shop floor not only accommodates existing customers, but also can serve as an investment in securing work from new customers.

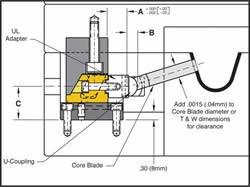

Read MoreHot Runner Temperature Control: A Low-Investment Solution for Challenging Molding

To understand the importance of hot runner controls, you need to examine how they actually control temperature, processing implications and mold design considerations.

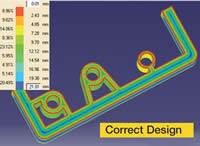

Read MoreBenefits of Using the Right Measurement Tool

How to accelerate design review with the right measurement tool and what to look for in the tools you select for measurement and checking of thickness on 3-D models.

Read MoreConsiderations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

Read MoreDesigning for Downstream

Steps can be taken to deliver to your customer not only a better performing tool, but a better performing tooling investment.

Read MoreCAM Software Aids in Quick Turnaround Tooling

CAM package works efficiently within CAD software—allowing a moldmaker to cut as quickly as possible to deliver molds in the shortest timeframe possible.

Read MoreSimplified Approach to Complex Five-Axis Machining

As multi-axis machine tools become more complex, CAM software systems must provide a more elegant way to program them.

Read MoreFeature-Based CNC Programming Cuts Programming Time by 25 to 75 Percent

Moldmaker switches to new programming software that auto-matically recognizes features and allows the programmer to define a process for the feature that can be repeated each time a similar feature is encountered; and, allows for more timesavings via its improved rest machining and trochoidal milling capabilities.

Read More

.jpg;maxWidth=300;quality=90)