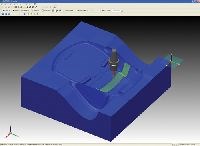

CAD/CAM Package Improves Speed, Accuracy And Design Time for Complex Molds

This blow mold manufacturer finds a software package that is able to work with complex curves and surfaces quickly and efficiently.

Carving out a niche in custom blow molds, Accu-Mold, Inc. (Latrobe, PA) needed a CAD/CAM package that could provide superior surface blending capabilities and work with curvy surfaces. Vice President Dennis Holby looked no further than Surfware, Inc. (Camarillo, CA) to meet its software needs.

In business since 1994, Accu-Mold’s blow molds run the gamut from toys and recreation to medical, industrial and home/gardening. Holby notes that Surfware’s SURFCAM Velocity 4 package is able to work with all of the extras the company’s molds are built with, which include pneumatic, hydraulic or mechanical moving cores and punches. “When a company comes to us with their proposal, they have to understand our process versus an injection molder’s process,” he notes. “We do a lot of molds today where we are converting from roto molding, and there are differences. Despite this challenge, we can help them redesign their molds to make them compatible with the blow molding process.” Fortunately for Accu-Mold, Velocity 4 fits the bill. When a molder chooses blow molding over roto molding, cycles times can be reduced from 20 minutes down to two or three minutes.

Ahead of the Curve

“We’ve been using Surfware since we first opened up our doors,” Holby recalls. “We knew we had to get into 3-D programs and Surfware was recommended to us. We’ve never turned back. They keep us constantly updated as part of their maintenance program, which entails them sending us e-mail updates and upgrades.

“When we first looked at all of the packages out there, it was Surfware’s capabilities with blow molding technology that sold us, particularly their surface blending technology,” Holby continues. “We believe it is the most technologically advanced. With blow molding, there is nothing straight about it, it’s curvy and twisty. With the Velocity 4 package, Surfware has pioneered this surface modeling technology with the ability to blend and trace curves.”

Holby notes a number of improvements on the shop floor. “Velocity 4 has improved speed, accuracy and design time,” he emphasizes. “Our employees were able to perform design tasks more quickly. Then, Surfware started getting more innovative on the CAM side with tool tasks like Z-level roughing to cut down on cycle times, which also has sped up cutting features on the machining centers. This has resulted in reduced cycle times and delivery times—and speed to market is even better.”

Holby just may be Surfware’s biggest non-employee sales executive. “I recommend it to a lot of shops, and have invited many other moldmakers to our shop to spend a half a day sitting at our stations to play with it,” he states. “We all want to know who has the better system, and I like being able to help them to make a more educated decision. If they like it, I give them the sales rep’s card.”

Accu-Mold has purchased multiple seats—some of which are right on the shop floor next to the machines. “They just don’t sit in an engineering room,” Holby says. “The designs are sent to those computers so the machinists can create their own toolpaths as they see fit. I do oversee it by regularly checking their work and addressing questions, but at the same time, I have other things to do. So they have been trained to create and change their own toolpaths. As part of ongoing training, I show them why something didn’t work, what they may have missed, etc. I want them to be independent of relying on someone else to do this for them so we don’t have employees standing around waiting on one guy.

“Of course there is some initial extra cost of doing it this way with the purchase of the additional seats, but it paid for itself real quick with added production time; and it eliminates that bottleneck of the programmer having several jobs to do when the machinists are involved,” Holby adds. “Things have to move through the shop quickly.”

Holby adds that he does all of the in-house training, with a Surfware rep only occasionally coming in to show “little tricks” and the latest updates. “Velocity 4 allows us to be very flexible for our customers,” Holby says. “We can easily translate a number of CAD data programs. Not all of our customers use the same system. It is the best program for our needs—helping us to design blow molds for 2-ounce bottles, 8-foot kayaks, and anything in between.”

Related Content

MMT Chats: Digitalizing Mold Lifecycle and Process Performance

MMT catches up with Editorial Advisory Board member Bob VanCoillie senior manager of Kenvue’s mold management center of excellence outside of Philadelphia to discuss mold management via tooling digitalization and OEM expectations and opportunities.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreHammonton Mold, ADOP France Forge Strategic Partnership in Injection Blow Moldmaking

Hammonton Mold Inc., a leading full-service mold shop based in New Jersey specializing in injection blow molds (IBM), proudly announces its official partnership with ADOP France, a prominent IBM mold manufacturer based in Normandy, France.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreRead Next

High-Performance Milling with a Tool Engagement Controlled CAM System

It is now possible to increase productivity without increasing cost by using a new milling technique—tool engagement milling.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)