Data Management Software

How to Optimize Your ERP Implementation

Proven methodology for using enterprise resource planning.

Read MoreGeometric Implements Large-Scale Desktop Virtualization with NetApp, Cisco and Citrix Technologies

Virtualizes 250 desktops using Virtualization Experience Infrastructure (VXI); Company to adopt cloud infrastructure to drive higher business productivity.

Read MoreToday's Tools for Tomorrow's Technology Leaders

As you investigate investment in capital equipment, training, services, or a myriad of other technology items, turn to this guide for assistance.

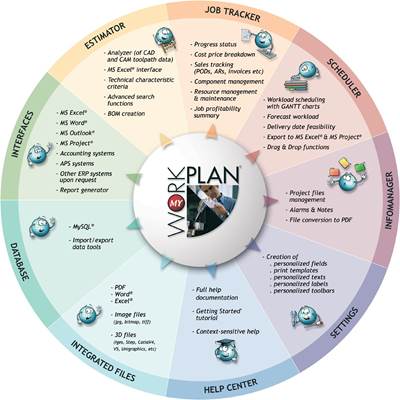

Read MoreToolmaker Benefits from ERP Software

WorkPLAN Enterprise ERP software integrates with SAP® for greater transparency at German toolmaker HARTING Applied Technologies. The company has 15 WorkPLAN Enterprise workstations in a Citrix terminal server environment enabling managers, controllers, technicians and the sales personnel to have access to relevant data on the central WorkPLAN Enterprise system.

Read MoreEngineering, Calculation and Reference Resource Software for Moldmaking

DZynSource for Molds software, version 3.0.0, has just been released.

Read MoreEarly Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

Read MoreThe Digital Office: Improving Efficiency and Productivity in Your Back Office

Simple and affordable document management solutions that can have a powerful impact on your shop’s bottom line.

Read MoreDetecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

Read MoreHow Success Happens

All too often lately, I sense a feeling of entitlement in some areas of manufacturing. I know how that sounds—U.S. manufacturers rightly believe that they’ve been bludgeoned over the past 20 years or so by government trade policies, along with a shifting perception in our culture that a career in manufacturing is in some way less-than-noble/lucrative/rewarding. But there are some SMMs that I speak with who say things are hopeless. They tell me that their industry and government have abandoned them, and there’s nothing they can do about it.

Read MoreMRP: Why You Need It and What It Can Do for Your Business

Choosing the right manufacturing resource planning system and ensuring it is implemented correctly will yield great benefits to your shop’s efficiency.

Read More