Data Management Software

Integrated Software Speeds End-to-End Moldmaking Operations

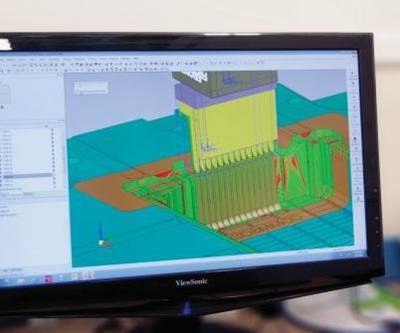

Cimatron CAD/CAM software from 3D Systems helped PTI Engineered Plastics simplify the flow of its work from design to production.

WatchHow Much Are Those Free Estimates Costing You?

Everyone says that time is money, yet many mold builders throw it away at an alarming rate by quoting for free. Check out what one cost estimator and automotive lighting specialist has to say about this industry challenge. If companies were to start looking at their costs to provide these ‘free’ quotes, they’d be surprised at just how much this is costing them.

Read MoreIt's Not for Me

Almost every time I speak with a moldmaker about their ERP, scheduling or quoting software, they say that what is on the market is not specific enough for what they do, and they end up developing their own solution. Well, here are five questions to ask to learn if it is time to change your ERP solution.

Read MoreRethink Moldmaking with Digital Tool Knowledge

Connecting digitized tool data with CAD/CAM, presetting, production and automated inventory control offers real-world productivity gains.

Read MoreThree Ways to Deliver Accuracy, Efficiency and Profits

A cloud-based ERP provider shares three ways that improved visibility can help small manufacturing operations leaders deliver accuracy, efficiency and better profits for the manufacturing team.

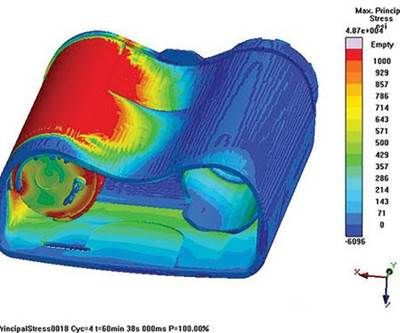

Read MoreMinimizing Costly Tooling Issues

Properly reviewing a mold design before manufacture can help avoid new tooling issues.

Read MoreEase Shop Management

One of the biggest challenges of properly implementing enterprise resource planning (ERP) software is making sure it includes all necessary information, but even a basic ERP solution can positively impact a mold shop.

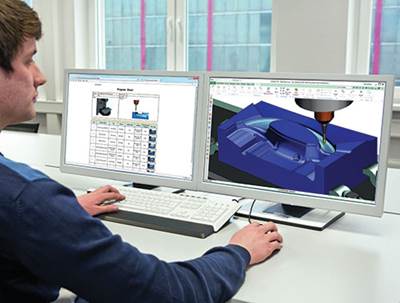

Read MoreBeyond Integration

CAD/CAM integration has reached an entirely new level of value within process planning.

Read MoreProduct Cost Management Improves Supplier Negotiation

Certain software tools can help take the guesswork out of the process for both manufacturers and suppliers.

Read MoreThe Data-Driven Operation

Manufacturing is a team effort involving suppliers, tool shops and customers throughout the world collaborating and sharing project data.

Read More