Cutting Tools

Toolroom Management: Presetting Increases Profits And Productivity

Guidelines for selecting the right tool presetting and measuring system to realize savings.

Read MoreMachining Trends for Drilling Coolant Channels in Mold Bases

How to reduce the costs and leadtimes associated with mold base manufacture by using multi-functional machines.

Read MoreHow to Choose and Size the Right Metalworking Filtration System

Understanding the importance of a properly engineered filtration system to the mold build process.

Read MoreFaster Cavity Roughing

Fresh eyes and replaceable-tip cutters triple moldmaker’s cavity roughing rate.

Read MoreHolders/Cutters/Inserts Combination Maximizes Productivity

A switch in cutting tools triples the output at a die stamping facility.

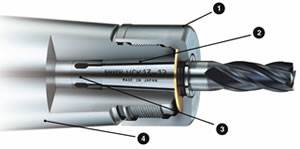

Read MoreHigh-Speed Collet Toolholder Or Shrink-Fit Tooling

An in-depth look at the benefits of a quality high-speed collet toolholder reveals advantages over shrink-fit tooling for most high-speed applications.

Read MoreDetermining the Value Of Your Cutting Tool

How to reach the break even point of your cutting tool investment within hours.

Read MoreHSK Fact and Fiction

Get the facts on what to consider when purchasing and using HSK tooling.

Read MoreIt’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

Read MoreWhat Ceramic Insert Technology Can Do for Moldmakers

The benefits of hard milling with ceramics in mold manufacturing.

Read More

.png;maxWidth=300;quality=90)