Cutting Tools

Machine Tool Expandability Through Efficient Retrofitting

Considerations for determining if retrofitting is the appropriate and economical solution for your shop.

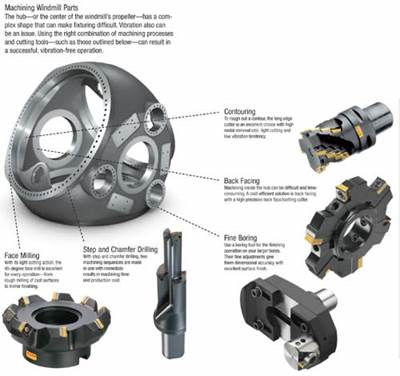

Read MoreWind Power Industry Opportunities Blowing Our Way

Moldmakers wishing to tap into this growing market should do their research and reach out to both wind power industry experts to learn about windmills and cutting tool suppliers to learn what it takes to enter this field.

Read MoreAdvanced Toolpaths Improve Cutter Performance in Difficult Materials

Trochoidal toolpaths are available on most CAD/CAM systems, yet are rarely used or even known. By using trochoidal toolpaths and hybrid trochoidal toolpaths you can successfully machine exotic materials.

Read MoreHydraulic Fluid Reduces Energy Consumption by Eight Percent

An energy-efficient hydraulic fluid has been developed for use with CNC machines that features low-deposit forming tendencies, provides equipment protection and can extend oil maintenance intervals.

Read MoreCutting Tool Slashes Cycle Times by 75 Percent

This moldmaker reduces cycle times from 10 hours to two hours with a more durable, faster cutter that also leaves a nice finish.

Read MoreElite Mold & Engineering: Team Elite

Being both a moldmaker and a molder allows Elite Mold to be a one-stop team for its customers and the MoldMaking Technology 2009 Leadtime Leader Honorable Mention Award: Small Shop.

Read MoreTool Balancing and Shrink-fit Holders Yield Successful Manufacturing Platform Overhaul

Investing in technology while improving processes and methods yields near 100 percent success rate on initial mold trials and 50 percent reduction in shop rework and scrap.

Read MoreAuto Nozzle Makes Minimum Quantity Lubrication Hands-Free

Minimum quantity lubrication, or MQL—also called near-dry machining—applies cutting fluid in ounces instead of gallons.

Read MoreConsiderations for a High-Feed Milling Strategy

High-feed milling is becoming the chosen methodology for removing as much material as possible in the shortest amount of time, as more shops equip themselves with high-speed CNC machining capability and sophisticated CAM programs.

Read MoreIncrease Productivity with Balanced Toolholder Assemblies

During these times of economic uncertainty, it’s more important than ever for manufacturers to make sure they are getting the most efficient and productive use of their equipment. Operators of machine tools can do this by finely balancing the tools and toolholders being installed on their machines.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)