What Ceramic Insert Technology Can Do for Moldmakers

The benefits of hard milling with ceramics in mold manufacturing.

In order to maintain a competitive edge in today’s global economy, mold and die manufacturers must continue to offer high quality products with exceptionally shorter leadtimes. To do this it is necessary to explore improved manufacturing techniques and cutting tool materials that will allow the mold shop to stay ahead of the competition. Hard milling is one of these techniques that continues to grow. Until a few years ago, moldmakers were unable to seriously consider hard milling operations due to the limitations of the machines and contemporary cutting tools. Today however, most modern machining centers with their rigid, high-speed spindles and advanced processors are well suited for cutting harder materials. Also, the leading CAM software packages have cycles specifically for hard milling with toolpath functions designed to optimize cutting tool life.

Hard Milling Tooling Options

Mold shops use three general types of hard milling tools: solid carbide endmills, indexable carbide inserts, and, most recently, ceramic indexable inserts. Each of these tools has its strengths and weaknesses depending upon the application. Solid carbide endmills are usually precision ground, coated and quite expensive. When the endmill gets dull, it must be re-sharpened and re-coated. However, after the endmill has been rehabbed, it generally does not always cut as well as the new endmill.

The second type of hard milling tool is a cutter with indexable carbide inserts. In most cases the carbide grades and geometry of these inserts are not designed well for hard milling, and they do not offer optimal tool life or productivity in hardened materials.

The third type is to use ceramic indexable inserts. More specifically, whisker-reinforced ceramic inserts. The benefits of using a system of cutters with indexable ceramic inserts include faster cycle times and a reduced number of operations per part. But the use of this tooling system requires both the programmer and operator to rethink the process of machining and pay attention to details that may not have been considered with other tools.

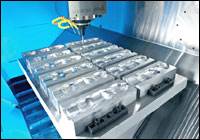

A full line of cutters for hard milling with whisker-reinforced ceramics enables a shop to rough out a part from a solid hardened block—including face milling, pocketing and profiling with indexable inserts—and finish it in one setup. Cutters engineered to mill with ceramics are capable of secure, high-speed milling from large face mills down to small diameter end mills—all using indexable ceramic inserts. It is important to use cutters designed for hard milling with ceramics at high velocity for secure insert clamping.

High velocity milling cutters are built for security and repeatability at ceramic milling speeds. Modern whisker-reinforced ceramics have a melting point of more than 2000o C, which means that ceramic inserts can operate at speeds well beyond the point where carbide tools fail. In fact, whisker-reinforced ceramics work better above the melting temperature of carbide inserts. Coolant is not recommended for hard milling applications with ceramic inserts, but air blast is suggested especially when pocket milling to keep from re-cutting chips. Reduced coolant usage and disposal cost is an added benefit when using ceramic inserts for hard milling.

Cost Savings with Ceramics

Hard milling with ceramic inserts can help a mold shop to reduce manufacturing costs in several ways. First, a mold shop can replace several operations with one operation. Instead of machining, hardening and remachining, the use of ceramic inserts enables a shop to harden the steel first and then machine the part in the hardened form. This reduces manufacturing time and improves job tracking by reducing the number of times that you must set up and move a component through various manufacturing phases. Furthermore, roughing a hardened part with ceramic inserts also can eliminate expensive and time-consuming EDM operations, as well as the need to make one or more electrodes.

Second, ceramic inserts are capable of machining hardened steel at much higher speeds than conventional carbide cutting tools. Combine the higher operating speed with the proper feedrate and a healthy step-over and the shop can achieve some impressive metal removal rates. Another key factor in increased production rates when hard milling is the cutter density. Every additional tooth in a cutter increases the cross feedrate. Higher speed and more feed add up to lower cycle times and money saved.

Third, many times the surface finish achieved by rough milling with ceramics leaves less work for a finish milling operation, and reduces finishing and polishing time. Milling at relatively light feedrates in hardened steel with carbide usually leaves a good finish, but many times with ceramic inserts the rough finish is even better than the required finish. In some cases, additional milling, grinding and polishing can be eliminated, saving several hours of manufacturing

Hard Milling with Ceramics—Application

Proper application of speed and feed for the material hardness are critical factors for good tool life when hard milling with ceramic inserts. Unfortunately, depth- and width-of-cut, as well as cutter lead angle, are commonly overlooked. A basic understanding of how these factors influence tool life can make a huge difference in metal removal rates. If a tool is running with the incorrect chip load or at inefficient speeds and feeds, it not only sacrifices tool life, but productivity as well. When considering all of the factors, productivity increases and decreases can be astounding with small changes in cutting parameters.

Speed

The cutting speed necessary for successful hard milling with ceramics is based on the actual material hardness, usually in the 45–65 Rockwell C hardness range. At elevated temperatures the metal being machined becomes plasticized, or softened, which lessens the cutting forces, and aids in chip separation. To take advantage of the strength and hardness of a whisker-reinforced ceramic insert, it is necessary to run at a surface speed (SFM) high enough to create sufficient heat in the cutting zone, which may be as much as five times the cutting speed of conventional carbide.

This is not to suggest that hard milling with ceramic inserts requires a new high-speed machining center with 50 horsepower and the latest advanced processor. The speed necessary for milling hardened materials with ceramics is within the range of many of the machines in a modern mold shop. The horsepower consumption is actually quite low due to the low cutting forces being generated. The ability to hard mill with ceramics on most machines already available in your shop is another benefit to the tooling system.

Feed

Before programming a hardened part it is important to consider the factors that influence the difference between the programmed feedrate per tooth and the actual thickness of the chip being formed. The feed per tooth specified in the program can be dramatically reduced by the cutting conditions. The actual thickness of a chip being formed is affected by the depth- and width-of-cut as well as the insert radius or the lead angle of the tool.

Actual chip thickness is a crucial factor for heat dispersion (i.e., the chip must have enough mass to carry away a majority of the heat). When the depth- and/or width-of-cut is below an acceptable level, the chip generated will not be thick enough to carry away all of the heat being produced by the cut. The heat that is not absorbed by a thin chip has to go somewhere. It will be pushed into the part, the inserts, the cutter and the fixture. It is much more efficient to send the largest portion of the heat away with the chips.

Feedrate and the effect on the actual chip thickness also are directly related to the insert’s cutting edge. Most ceramic inserts require some edge protection such as a negative land commonly know as a T land in addition to a light hone (.0005”-.001”). The inherent edge strength of whisker-reinforced ceramics allows the insert to mill difficult materials with only a small negative land (.002”-.004”). This land helps strengthen the insert by redirecting the cutting forces into the body of the insert, which puts the cutting edge into a stronger, more compressive condition. The edge condition must be taken into account when hard milling with ceramics to ensure that the actual feed is at or above the negative land on the insert. A chip that is too thin works on the very edge of the insert, where it is the weakest, causing premature insert failure.

Lead Angle Effect on Chip Thickness

In many cases ceramic milling cutters are specified with a lead angle, or more commonly, with round inserts. The lead angle of a cutting tool reduces the programmed chip thickness by an easily calculated percentage.

For instance, on a milling cutter using square inserts on a 45-degree lead angle the actual chip thickness will only be about 70 percent of the programmed feed per tooth. This would allow you to increase the programmed feedrate by up to 40 percent to achieve an equal ratio of programmed feed to actual chip thickness. The same principle applies to cutters using round inserts.

The lead angle on the radius of a round insert is infinitely variable based on the depth-of-cut. This makes it more difficult to calculate the percentage of chip thinning with a round insert. However, this is a common issue that must be addressed when using ball nose and bull end mills, and many machinists and programmers in the moldmaking industry are familiar with the chip thinning compensation formulas. If you consider a ceramic milling cutter using round inserts like a bull nose mill, and apply chip thinning compensation for the radius of the insert you will assure proper chip formation. In this way you also can see increased feedrates of 20 to 40 percent over the initial programmed feed, and metal removal rates many times that of carbide end mills.

Conclusion

Hard milling may not be the solution for everyone, but for those shops that need to squeeze every bit of productivity out of their operations while keeping costs to a minimum, it should be seriously considered.

At the end of the day, the benefits of decreased cycle time, the predictability and indexability of ceramic inserts, a reusable toolholder system and great surface finishing capabilities add up to an impressive potential for productivity and cost savings. More productivity at lesser cost means more work through your shop. And that’s a good thing.

Although it may have been determined years ago that ceramic inserts are not an option for milling in the mold industry, the technology has matured and the tools are available. Perhaps today would be a good time to rethink the possibilities it can bring to your shop.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Looking Sharp

Advancements in cutting tool/toolholder construction yield better stability and higher accuracy to achieve greater feedrates and increased productivity.

Read MoreTaking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.png;maxWidth=300;quality=90)