Case Study

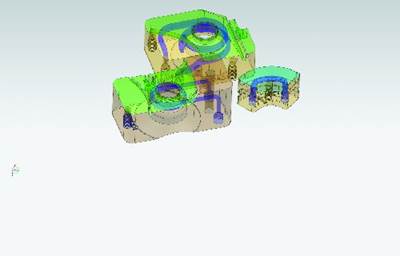

Conformal Cooling: Another Tool to Build a Better Mold

Moldmakers are just starting to scratch the surface of what can be done with conformal cooling, which involves an additive approach.

Read MoreAerospace, Medical Expansions Solidify Niches

Dynomax Inc. has earned the prestigious AS9100 Revision C quality certification.

Read MoreThermography: From Benchmark to Diagnostic Tool

It all starts with a part. There’s a problem. Whether it’s a cosmetic appearance issue, or perhaps a dimension out of tolerance it’s relatively easy to identify if there’s a problem. However, a diagnosis based on that same visual observation will also likely not identify the root cause.

Read MoreReduce Tooling Costs and Time with Laser Scanning

Aircraft Technologies, Inc. (San Antonio, TX)—a leading manufacturer of toilets for corporate jets—saved $20,000 and four weeks in reduced tooling costs/time for a new model by utilizing NVision’s (Coppell, TX) laser scanning and engineering services.

Read MoreDental Equipment Manufacturer Uses Digital Prototyping as its Primary Design Tool

With Autodesk Inventor Digital Prototyping software the company can integrate everything in one place and see a complete prototype before anything is built.

Read MoreTaking Streamlining to the Next Level

Based in Rochester, NY, Aluminum Injection Mold Company (AIM; Rochester, NY) is an industry pioneer in providing creative production aluminum tooling solutions to a wide range of markets including automotive, medical, computer / business machines, telecommunications and consumer products since 1985.

Read MoreMoldmaker’s Plant Expansion Increases Ability to Repair Worn, Damaged Molds

Monroe Mold (Monroe, MI)—a manufacturer of bottle-specific molds and tooling for all extrusion blow molding platforms—recently completed a plant expansion that not only adds to its manufacturing capacity but also allows the company increased ability to repair damaged or worn molds, a market segment that has shown growth.

Read MoreMedical Niche and Proprietary Product Equal Success

Fitchburg, MA-based Micron Products has been supplying the medical industry with quality medical components for more than 30 years and has also made a name for itself by producing its own line of silver/silver chloride sensors, metal and carbon filled studs that are used throughout the world in the production of disposable electrodes for ECG, EKG, EEG and EMG applications.

Read MoreClean Room Addition Expands Medical Moldmaking Niche

Micro Mold Co., Inc. and Plastikos Inc.—sister companies both based in Erie, Pennsylvania—recently completed a medical-focused facilities expansion with the addition of a clean room to further serve its medical customers and secure new business in this growing industry.

Read MoreCraftsmanship, Customer Satisfaction Keys to Success

Custom Mold & Design (CMD; Minneapolis, MN) designs and builds fully interchangeable, fast-cycling, high-precision injection molds.

Read More