Automatic Robot Performance Monitoring in the Mold Shop

Precision manufacturers can now monitor collaborative robots from Universal Robots in real-time to drive automation that improves performance and reliability.

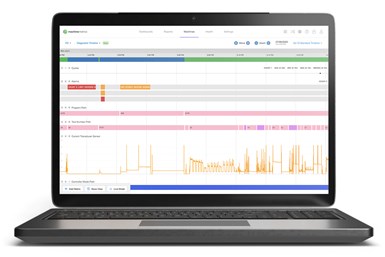

MachineMetrics, a provider of machine connectivity and production analytics for manufacturers, is making its Connector available for Universal Robots (UR) to easily connect to and capture valuable data from any equipment from UR. This latest connector, now available through the UR+ program to all current UR cobot users, enables instant insights into the health and performance of its cobots. Now manufacturers can maximize the uptime of their cobots to increase productivity and drive additional throughput with no additional head count.

“MachineMetrics, like Universal Robots, is at the forefront of delivering innovative solutions that lower the barrier to automation for manufacturers,” Christopher Savoia, regional head of the UR+ Ecosystem, says. “Their unique ability to deliver real-time insights into the health and performance of UR collaborative robots means increased reliability, uptime and productivity of automated work cells.”

Monitoring collaborative robots (cobots) from Universal Robots in real-time can drive automation that improves performance and reliability, even for moldmakers. “By connecting UR cobots to MachineMetrics, users can now gain real-time insights into cobot productivity, alert teams when issues arise, and remotely troubleshoot and diagnose issues to get the cobot back up and running,” Bill Bither, MachineMetrics CEO and co-founder, says

MachineMetrics’ connectivity system is designed so customers can capture data from any piece of factory floor equipment in minutes. The company says users can install it themselves without the need for expensive and time-consuming system integration work. Once installed, the data is instantly and securely streamed to the MachineMetrics Cloud Platform where users can visualize and analyze data from any asset.

On its own, MachineMetrics can let the right person or system know at the right time what is happening to keep machines running. In an autonomous factory powered by MachineMetrics, machine data can trigger an action by a robot that feeds the bar into the machine without human intervention.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.jpg;maxWidth=300;quality=90)