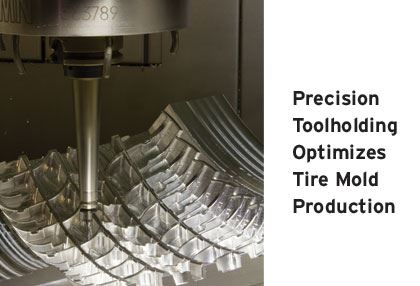

Precision Toolholding Optimizes Tire Mold Production

Case Study / Toolholding / Automotive

Tire molds can be just as, if not more, complex than many high-end aerospace components. Engineers are constantly changing and developing new intricate, complicated tire tread patterns—especially those that carry around to a tire’s sidewall— which pose significant machining challenges for mold shops such as Northeast Tire Mold.

The Akron, OH, tire mold shop direct machines its tire molds from solid blocks of raw material as opposed to producing them from castings. Each mold consists of several—usually eight to 10—individual direct-machined segments that are then combined to form the complete round mold shape.

The Challenge

The machining challenge is that each mold segment is pitched, and there can be up to 12 different pitches to contend with around the full circular shape of a mold. And if tread patterns alone aren’t complicated enough, they must be machined at these same pitches, match up from one segment to the next and take into account for heat expansion that will occur during the molding process.

In addition to having to contend with basically no truly flat surfaces in a direct-machined mold, Northeast Tire Mold must hold exacting machined tolerances so that its molds generate tires with no more than 0.005” total indicated runout (TIR), which means the shop must hold its individual machined mold segment tolerances to +/- 0.001” and well under 0.003” for the entire mold.

Toolholding Solution

The process of direct machining molds started as early as the 1960s, but the process was time consuming and very expensive. It became much faster and more cost effective with the advent of advanced 5-axis machining and the development of associated software. Full, simultaneous, high-speed 5-axis machining capability and supporting software is now a must for direct machining tire molds. However, what Northeast Tire Mold discovered was that 5-axis direct machining of tire molds also requires rigid, dependable, high-precision toolholding that allows the shop to run its two 5-axis machines to their full speed and feed capacities for optimizing mold production.

Prior to purchasing its first 5-axis machine, Northeast Tire Mold opted for the powRgrip toolholding system from REGO-FIX. The shop now has one powRgrip unit, a REGO-FIX tool balancing system and about 200 powRgrip toolholders, including collets and cylindrical shanks for extending tooling reach up to 11.8” long.

Unlike other clamping systems where heat or hydraulics are used to expand the material, the powRgrip system uses the mechanical properties of the holder material to generate tremendous gripping force with run-out below 0.0001”. Designed for easy operation and use, the system allows Northeast Tire Mold to press in tools or remove them from holders in less than 10 seconds. And because no heat is involved, tools can be used immediately after a tool change.

The holders provide Northeast Tire Mold with strong, precise and balanced toolholding and very low cutter runout, along with increased tool life and improved surface finishes. Additionally, according to Mike Christie, vice president of Northeast Tire Mold, the powRgrip tooling offers several advantages over shrink-fit type toolholding, which the shop did, at one time, consider for its 5-axis machining operations.

“powRgrip collets and holders last longer. We’ve been running our REGO-FIX collets for six years, and they are still like brand new. Over this same time period, we would have already had to replace holders if we were using heat-shrink,” says Christie. “The powRgrip tooling also provides quicker tool changeouts as compared with heat shrink holders. Plus, the system accommodates much smaller size tooling than do heat-shrink holders and reduces our tooling inventory because one holder can be used for a range of different cutter sizes, as opposed to shrink-fit holders where we would need one holder per each cutter size.”

For tire mold machining operations, Christie says that the extremely low TIR provided by the powRgrip holders is critical because the shop uses very small cutters at lengths of up to 15 times cutter diameter. For instance, a 0.027” diameter two-flute end mill at a length of 15 times cutter diameter will often be used to machine to depths of 0.190” in aluminum tire molds. And for such an operation, less cutter runout means more accurate machining, but most importantly, longer tool life, which in this instance, according to Christie, is about 1,400 minutes as compared with the few hundred minutes of tool life if a heat-shrink holder were used.

Toolholding in Action

Northeast Tire Mold manufactures about 250 molds annually that are used to produce various tire sizes up to 6’ in diameter and for vehicles ranging from ATVs and motorcycles to passenger cars and light duty trucks. Most molds are made from 1020 steel or 6061 aluminum, and machining time per mold segment can take anywhere from 3 hours to 16 hours, depending on tread pattern complexity.

The shop’s two Alzmetall 5-axis machines run 24/7, and lights out, with one programmer using OpenMind software. The machines each have a capacity of 60 tools, and on average, 40 tools are used per each part program. Some tools are redundant because the shop knows exactly how long certain tools will last and wants to have replacements ready to keep the machines continuously running.

Using all carbide cutters mounted in nothing but REGO-FIX holders, the two 5-axis machines, each with a 30-hp spindle, cut mold segments at spindle speeds of 24,000 rpm and at feedrates as fast as 315 ipm. Individual mold segments are machined one at a time and in only two machine set ups–backsides are machined first, then the part is flipped for machining the fronts.

Northeast Tire Mold machines most of its steel mold segments dry, while aluminum ones are done with coolant using REGO-FIX coolant-fed collets. Christie notes that a lot of the shop’s small tools aren’t coolant-through, and the REGO-FIX collets feature three slots that direct coolant to the cutter for lubrication and to evacuate chips that can cause cutter breakage.

The machining strategy for molds at the shop is to remove as much stock as possible, as quickly as possible, in the rough pass, then run a finish pass. And with its high-end machines and REGO-FIX tooling, Northeast Tire Mold achieves such superior surface finishes, that secondary benchwork is drastically reduced or in some cases eliminated altogether—except for a final sandblasting operation. Often shops will spend up to 40 hours benchworking just one mold segment, while Northeast Tire Mold has slashed that time to 8 hours for a comparable mold segment.

Summary

“When you consider the amount of people and machines we have, we are outperforming our competitors 2 to 1,” explains Chris Sipe, president of Northeast Tire Mold. “What takes them as many as four separate machines, we are doing with only two. And the key to that level of production is our skilled programmers and machinists, advanced machine tools, software and precision tooling, but most critical is that we have our moldmaking processes down pat.

“We deliver completed tire molds in 8 weeks or less, and for some experimental molds, we’ve delivered within 10 days,” he states. “Also, our molds are so accurate that customers have the option of replacing only individual segments knowing that the new one will fit and match perfectly to the other existing segments. We were the first to offer such capability to customers.”

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Thermal Toolholding Yields Benefits for Moldmakers

By using thermal toolholding, moldmakers can achieve improved accuracy and greater tool life, as well as better mold surface finish.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)