Basics

A Case for Collaboration

This alliance of mold manufacturers will likely continue long after the incentives driving its creation become irrelevant.

Read MoreThe Potential of Enhanced Venting Materials

Stop fighting venting problems with mold retrofits and prevent them by designing the original mold with an enhanced venting steel.

Read MoreMold Builder Brings STEAM to its Facility

Recently M.R. Mold & Engineering teamed up with a local high school to help promote a program called STEAM: Science, Technology, Engineering, Art and Math, and the results were amazing.

Read MoreDesigning a Better Heat Exchanger - Part 2

In part two of our three-part sub-series on mold water cooling systems, we review water quality and its impact on mold performance.

Read MoreMold Water System Basics

Molder to moldmaker: “If you want the project, you need to hit the targeted tooling costs.” Then oftentimes the moldmaker builds a tool that fits the budget, but does not have the best performance with regards to water. Here are some basics about the impact of mold's water system.

WatchSystem Cooling

The efficiency of the mold cooling circuits are critical to a stable process and the manufacturer of high quality, dimensionally stable parts. Now a new System Cooling platform gives molders the ability to monitor water flow and temperature circuits inside the mold.

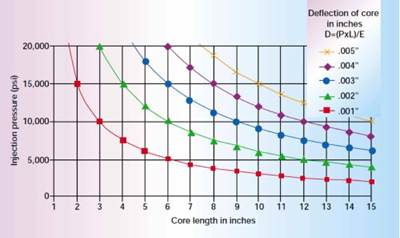

Read MoreIn Search of the Infinite Processing Window

Side-action preload can yield zero core movement during injection and help molders achieve a robust molding process.

Read MoreControlling the Melt Delivery System Heat Source

Understanding the heating systems along the melt delivery path is critical to setting up a robust process and properly diagnosing problems.

Read MoreThree Keys to Success at Eifel Mold & Engineering

For every decision, this toolmaker makes a point to consider the potential impact on three interrelated considerations: people, process and technology.

Read MoreVIDEO: How to Machine a Football

We are in the heat of football season, so what better time to showcase how a football is machined.This video shows a model American Football being created out of 6061 Aluminium with a Toyoda UX-570 5 axis machine with a 3D offset toolpath: 0.032 dia cutter mounted in a Typhoon HSM Jet Spindle using thru spindle coolant at 36,000 RPM and 400 IPM.

Read More