Basics

Transition to In-House Welding

Bringing laser welding in-house can help mold shops reduce shipping and handling costs while improving mold quality, lead time and overall customer service.

Read MorePlastic Injection Molding Starts with the Pellet

This is the first article in a new series that will examine the injection molding process by breaking down the path a plastic pellet takes as it is transformed from Pellet 2 Part. It covers what every moldmaker should know about raw materials, including the fundamentals of viscosity curves, Melt Flow Index, Melt Flow Rate, shear and more.

Read MoreWant to Know What We Are Celebrating in 2015?

It could be your shop's success, if you told us about it! Have you improved your leadtimes, increased sales, entered a new market, implemented a successful strategy or invested in proven technology that greatly impacted your manufacturing process? If so, then tell us. Your story could be grounds for Leadtime Leader Award consideration. A simple entry form is all it takes to be on your way to entering our annual competition.

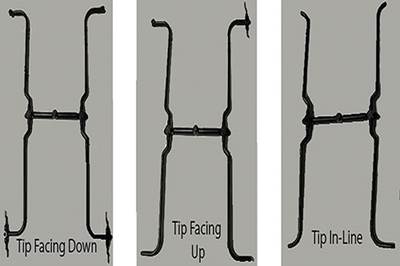

Read MoreUnderstanding Hot Tip Design

Alternative designs are available that will either eliminate or dramatically reduce skewing the flow of plastic.

Read More"If You Can Do It with Toys, You Can Do It with Anything"

Those are the words of Michael Araten, President and CEO of The Rodon Group and K'NEX Brands, during the Manufacturing Day event I attended last Friday at their Hatfield, Pennsylvania facility. He was referring to the "patriotic capitalism" the company embraces, which has resulted in the reshoring of most of the work they outsourced to China.

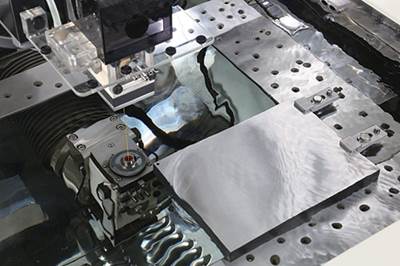

Read MoreIn-House Laser Welding Offers Quick ROI

Increasing pressure for ever-faster turnaround has made outsourcing this operation impractical for these three providers of mold repair and maintenance services.

Read MoreTruly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

WatchMaking Chips at IMTS

Philip Paull, of Noblesville, Indiana, owner of Excavating Solutions, won the Hurco Chipmaker Challenge Championship at IMTS in Chicago last week. The prize package Paull won includes a brand new Hurco CNC mill worth more than $100,000, a tooling package from Sandvik Coromant and $10,000 of Hurco bucks that can be used for training or machine options.

Read MoreMarketing Basics for Moldmakers

Address these three marketing basics to quickly get up to speed on creating an online presence that improves your shop’s visibility.

Read More