Basics

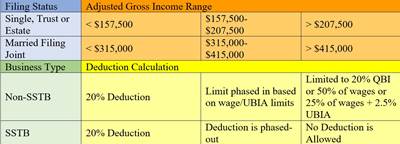

Understanding the New Flow Through Deduction

The qualified business income deduction of the Tax Cuts and Jobs Act gives mold shops a 20-percent deduction of qualified business income to all non-corporate taxpayers, but it comes with some qualifications, restrictions, and limitations.

Read MoreAmerimold 2019 Update: What You Should Know about Additive Manufacturing for Conformal Cooling

This panel discussion will present in detail the different AM technologies available today, their advantages and disadvantages, and specific ways to implement these technologies without issue.

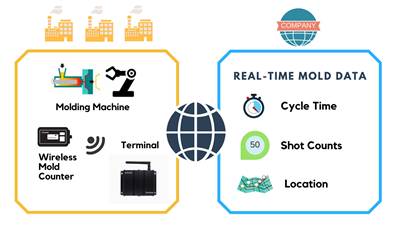

Read MoreMachine Learning for Mold Monitoring 101

Outsourced tooling supply chain management system offers data automation, more in-depth tooling analytics and performance trend measurements.

Read MoreHow to Better Balance Family Molds

A servo-driven valve gate can provide superior processing for family molds with significant variances in part sizes and volumes.

Read MoreHow to Improve Melt Distribution with Diffusion-Bonded Manifolds

Diffusion bonding for manifold manufacturing offers design freedom for optimizing hot runner melt distribution, reducing color change-over time, cavity-to-cavity weight variation, peak injection pressures, melt degradation, and resin flow stress.

Read MoreMaintaining Mold Components

Toolroom technicians must include frame plates, frame components, and cavity tooling when developing a mold maintenance plan.

Read MoreSurface Treatments Protect Mold Finishes, Reduce Downtime and Part Failure

Surface treatment vendors are expanding their services to include more treatment options, advanced technologies and convenience.

Read MoreHow to Avoid Tool Steel Corrosion

A mold builder should consider corrosion resistance, hardness, machinability, processing, polishability, operational environment and wear resistance during tool steel selection.

Read MoreHow to Offer Employees More Than a Normal Job

Austrian moldmaker Haidlmair focuses on its 550 people in a very unconventional way, as it continues to be a leading specialist in building high-quality tools for beverage crates, folding boxes, and garbage containers.

Read MoreHow to Hard-Mill Effectively

These are five rules for improving cutter performance and cutter life while maintaining tight tolerances during hard milling.

Read More

.jpg;maxWidth=400;quality=70)