Basics

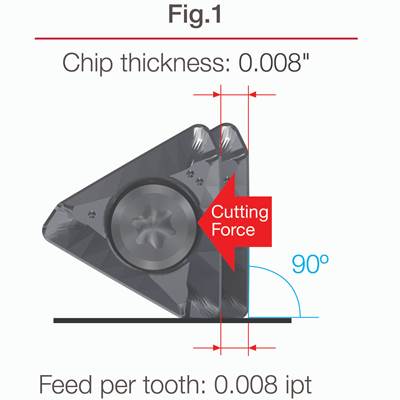

How to Achieve Accelerated Milling

High-feed milling reduces cycle time and extends cutting tool life.

Read MoreHow to Make the Switch from Negative to Positive Tool Offsets

Tips for changing from traditional touch-off methods to an offline presetter to optimize spindle times and reduce errors.

Read MoreTooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

WatchUnderstanding Manifold Thermal Expansion

Molders, mold builders and repair technicians must fully understand thermal expansion to ensure they don’t damage critical seals during manifold repairs or routine cleanings.

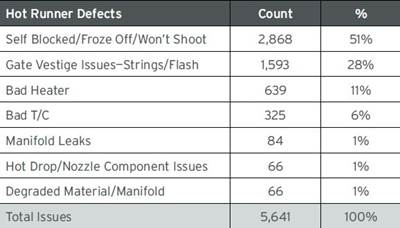

Read MoreMold Maintenance Refresher

As I hit the road to attend a hot runner maintenance workshop this week, I’m reminded of my last maintenance-related education session. So, I thought I’d share some images and tips as a little refresher on what I learned.

Read MoreTips for Mitigating Chatter and Vibration

A review of the problems of machine vibration and the strategies and tooling systems that that can stop them.

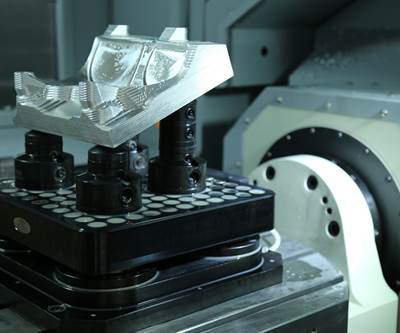

Read MoreHow to Design and Analyze the Right Clamping System

The use of innovative clamping systems to optimize the moldmaking production process requires consideration of five factors based on Industry 4.0 principles.

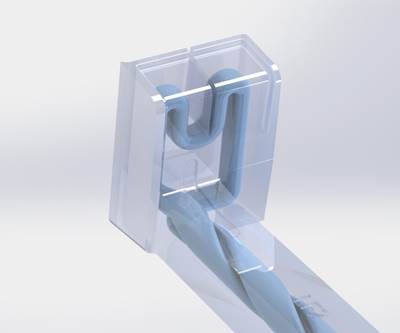

Read MoreSelling the Value of Additive Tooling in a Mold

Gaining molder buy-in for a conformal-cooled mold insert requires communicating the mold’s total cost of ownership over the life of the project.

Read MoreNew Series: A People+People Plan to Win the War on Talent

It’s no secret that it’s an employees’ market and companies of all sizes are struggling to attract, engage, and retain staff. Modernizing your talent strategy is key.

Read MoreHow to Maintain and/or Upgrade a Robot

Create a strategic plan to manage the lifecycle of a robot.

Read More