Basics

Understanding Business-Meal Deductions

Mold builders must account for meals and entertainment separately, as no deduction is allowed for entertainment in 2018 and beyond.

Read MoreRethinking How to Polish

Internal process documentation helps polishers build upon experience and overcome surface finish challenges.

Read MoreHow to Create an Accurate Budget

Proper financial planning is integral to the success of every mold project.

Read MoreHow to Build Manufacturing Awareness with Events

Six best practices for hosting community events that promote industry engagement.

Read MoreHow to Reduce a Mold Shop’s Top Effective Tax Rate

U.S. Treasury and the IRS proposed rules on new flow-through deductions.

Read MoreTen Tips for Effective Design-for-Manufacturing Analysis

MoldMaking Technology editorial advisory board member Andrew Garstkiewicz of GE Appliances, a Haier Co., offers sage advice on DFM analysis.

Read MoreHow to Set Accurate Manifold Preventive-Maintenance Frequencies, Part 3

The only thing that can mess up a solid PM plan for a manifold is a poorly designed system, and there are a variety of manifold designs and complexity levels. Many design features are the root cause of postponing a manifold PM until it breaks down.

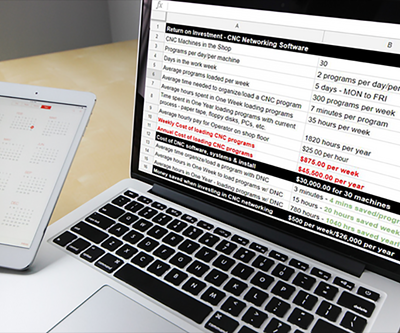

Read MoreTips for Selling the Value of Automation

How to prove automation saves time on the shop floor.

Read MoreHow to Set Accurate Manifold Preventive-Maintenance Frequencies, Part 2

The key to developing accurate and timely PM work instructions is understanding the impact of environmental factors on manifold performance.

Read MoreCT Scanning Accelerates Corrections on Injection Molds

Industrial computed tomography scanning (CT scanning) is a quality-assurance technique that is making its way into mold shops for speedy adjustments and corrections on injection molds, but only if it is used correctly.

Read More

.png;maxWidth=400;quality=70)