Automation

Smart Tooling

Combining cavity sensors with hot runner valve gate control yields new applications and greater process gains.

Read MoreAdding Value with Robotics

A robot may not directly make the final part, but it can add value to the overall process, if its use is properly planned and executed.

Read More"Smart" Technology

Although knowledge and expertise is just as important as ever, technology continues to advance toward almost thinking on its own.

Read MoreThe Data-Driven Operation

Manufacturing is a team effort involving suppliers, tool shops and customers throughout the world collaborating and sharing project data.

Read MoreFlexibility, Low Overhead Seed Sustainable Success

Robotics, cross-training and efficient use of available floorspace help this shop adapt to the ebb and flow of business.

Read MoreThe Will and the Way to Automate Mold Design

Persistence and the right technology enabled this automotive toolmaker to give programmers a head start on new projects and dramatically reduce calculation times.

Read MoreUntapped Production

Automation allows this mold manufacturer to run its EDM machines nonstop for months.

Read MoreControlling Costs by Controlling Production

A process-driven manufacturing strategy and extensive data tracking have enabled this company to double down on the advantages of integrated toolmaking and molding capability.

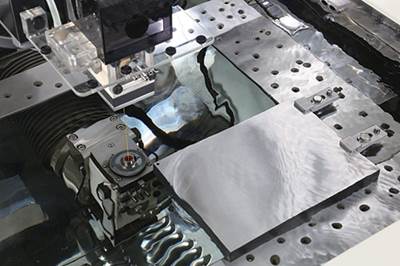

Read MoreTruly Smart EDM

Think ease of use, ergonomics and expertise when empowering your operators with the right EDM.

WatchBanking on Five-Axis Capability

Thanks to features that facilitate lights-out operation and an unusual, trunnion-type configuration, this shop expects its first five-axis machining center to keep it competitive for years to come.

Read More

.jpg;maxWidth=300;quality=90)