Automation

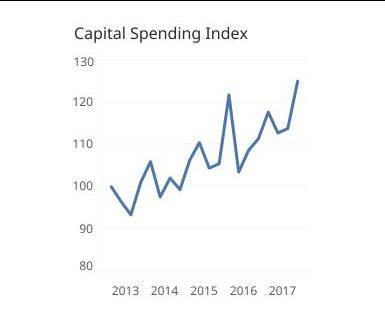

Gardner Industry Report: Automotive

New technologies coming to market in the next few years will require investments that will create sustained demand and industry growth for advanced automation, machinery, tooling, composites and plastics.

Read MoreTechnology Tuesday: Automation Fuels Productivity

Cruise through this week’s Technology Tuesday blog to see ways in which automation is boosting productivity and efficiency in moldmaking.

Read MoreLessons Learned in Deep Hole Drilling

Of course when it comes to deep hole drilling, the tooling, the fixturing and the automation are all essential, but the part that caught my attention during a recent UNISIG event was the focus on mold-specific industry solutions, especially its USC-M series machines that allow multiple operations to be performed on all workpiece sides with one setup.

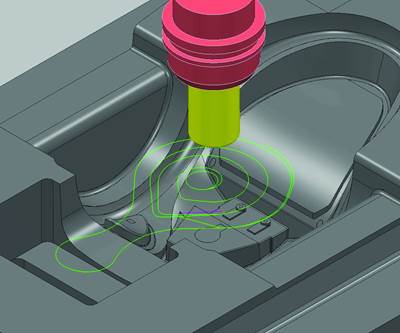

Read MoreCAM Tools Automate Programming, Aid Five-Axis Machining and More

The right software tools can help a shop realize the full potential of its workforce so that it can better meet increasing customer expectations.

Read MoreRealizing EDM's Full Potential with Automation

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing.

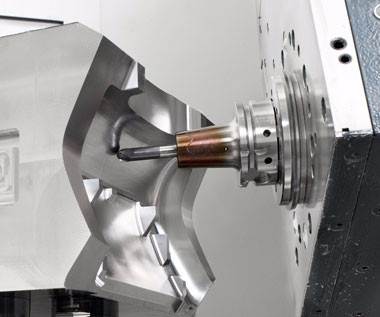

Read MoreShrink-Fit System Helps Moldmaker Boost CNC Accuracy, Productivity and Tool Life

Fine tuning a CNC machine for maximum speed and having the ability to run lights-out machining means controlling a wide variety of elements like tool holding. The inherent benefit of shrink-fit technology, as compared to other tool holding options, is that it virtually eliminates the toolholder as a variable for error.

Read MorePre-Machining Best Practices for Industry 4.0

Emphasis on technology that streamlines processes and provides repeatable outputs in your machining operations is key to automation and data-driven intelligence. Here are some common pre- and in-process attributes to consider as they pertain to process efficiency and reliability.

Read MoreTechnology Tuesday: EMO Wrap Up on EDM, Automation and Industry 4.0

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing. EDM technology is evolving through new machine designs, thermal stability, powerful generators, parts handling robots, linear handling systems and software solutions for future Industry 4.0 infrastructures.

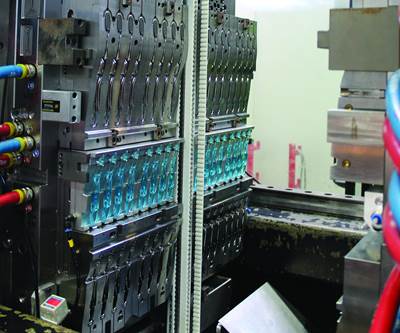

WatchInternational Perspective: Tooling Systems Squeeze More Production out of Each Mold

Multi-component tooling systems squeeze more production out of each mold.

Read MoreUsing Automated Technology to Fill the Skills Gap

Process automation is one of the fastest-growing strategies for overcoming capacity constraints in a mold shop.

Read More

.jpg;maxWidth=300;quality=90)