Automation

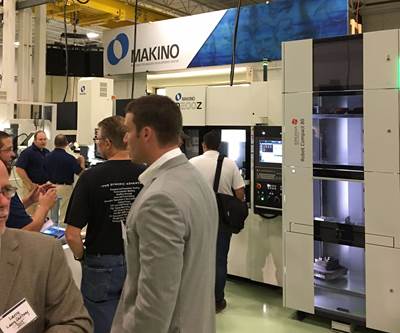

Moldmakers Share Benefits of Makino Die/Mold Expo

Three mold manufacturers share their takeaways from the recent Makino Die/Mold Expo.

Read MoreCobot in Action

The Motoman HC10 is the first collaborative robot to be introduced by Yaskawa outside Japan. HC stands for “Human Collaborative”. The prototype, with a range of 1.2 m and handling weight of 10 kg, is planned to be certified according to technical specification ISO TS15066.

WatchThe True Cost of Cobots

Defining expectations and determining the ROI of collaborative robots help guide sound investment choices.

Read MoreTechnology Showcase: Heading to Westec?

If you’re planning to head west to attend Westec, billed as “the West Coast’s Leading Manufacturing Event,” today’s blog is a slideshow preview of products you can expect to see there.

Read MoreInvest Now in Die/Mold Automation to Meet Growing Customer Demand

In today’s highly competitive global marketplace, there are two types of mold shop owners, (1) those who invest in new technology and automation to create innovative ways to meet customer demands for shorter lead times, more complex designs and tighter tolerances and (2) those show don’t invest and quickly fall behind other North American shops and low-cost, offshore manufacturers. Here is a case study from Makino about one mold builder who fits nicely into type number one.

Read MoreLights, Smart Phone, RECRUIT!

Elena Valentine, CEO of Chicago-based Skill Scout Inc., an experiential hiring firm, gives manufacturers some valuable tips about how to attract and hire the next generation workforce.

Read MoreMMT's 2020 Leadtime Leader Award Winner Is ...

Precise Tooling Solutions of Columbus, Indiana!

WatchWhat’s Your ‘Secret Ingredient?’

Given all the mold manufacturing companies I’ve visited or learned about, one detail continues to ring true with all of them: That “secret ingredient” to building a top-quality mold.

Read MoreICYMI, International Perspective: From Craftsmanship to Production

To be successful, a shop must be better, faster, more efficient and more flexible than the competition, and this requires automation across all of its operations.

Read MorePowerful Production

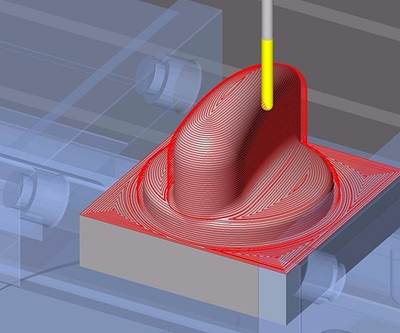

Automated cells with RFID technology facilitate a “productionized” approach that helps this shop make molds more accurately and efficiently.

Read More

.jpg;maxWidth=300;quality=90)