3D Printing

Giving Mold Builders Additive Capabilities, Super Creativity

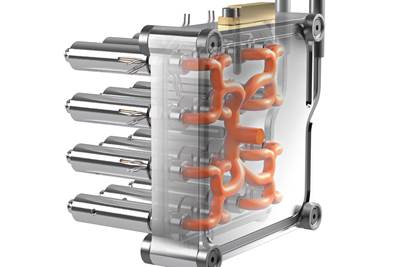

I saw my first 3D-printed hot runner manifold at K 2019 in Germany, but the system did not have a name yet. Fast forward to 2020 and it not only has a name, but it’s been successfully implemented in a number of applications across Europe. And today, it’s ready for the North American marketplace.

WatchTool Steel Alloy For Binder Jetting Delivers High Hardness and Strength

Digital Metal and its DM D2 tool steel alloy for AM can be heat treated to high hardness and compressive strength. Offers versatility and high wear resistance.

Read MorePatented AM Process for Functional Multi-Component Parts Production

Arburg Freeformer and AFP process enables 3D plastic part build layer-by-layer with high material diversity and high part quality.

Read MoreSiemens, Stratasys Partner to Incorporate Additive Manufacturing into Volume Production

The formal partnership aims to strengthen and expand the benefits of 3D printing in manufacturing value chain, with the aerospace, automotive and tooling industries expected to benefit first.

Read MoreHow to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read MoreMarkforged Report Suggests 3D Printing Enabled Manufacturers to Persevere Through COVID-19

Data shows that manufacturers using 3D printing were able to continue normal operations and innovate, while saving time and money.

Read MoreEOS, Texas A&M University Offer AM Professional Development Program

Successful additive manufacturing pilot training program for NASA Johnson Space Center leads to new collaborative offering to business and academia.

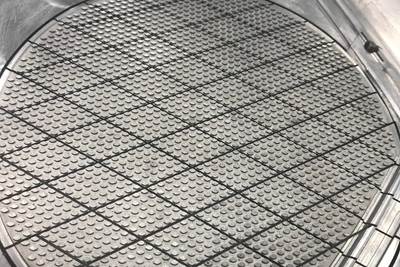

Read MoreMetal Binder Jetting System Features Enhanced Resolution

Desktop Metal’s Shop System uses binder jetting technology to 3D print metal parts at exceptional finenesses and resolutions up to 1600 DPI.

Read MoreAgemaspark Purchases 3D Metal Printing Machine, Improves Efficiency of Mold Tool

The EOS 290 enables manufacturing of mold tools through a conformal cooling technique to produce laser-sintered inserts. The technique improves efficiency of a mold tool by as much as 20%.

Read MoreESPRIT, Alma CAM Partner for Robot Additive DED Programming

The collaboration brings together additive toolpath planning in both subtractive and additive areas, and robots retrofitted for DED applications for a complete programming solution.

Read More