Tool Steel Alloy For Binder Jetting Delivers High Hardness and Strength

Digital Metal and its DM D2 tool steel alloy for AM can be heat treated to high hardness and compressive strength. Offers versatility and high wear resistance.

Share

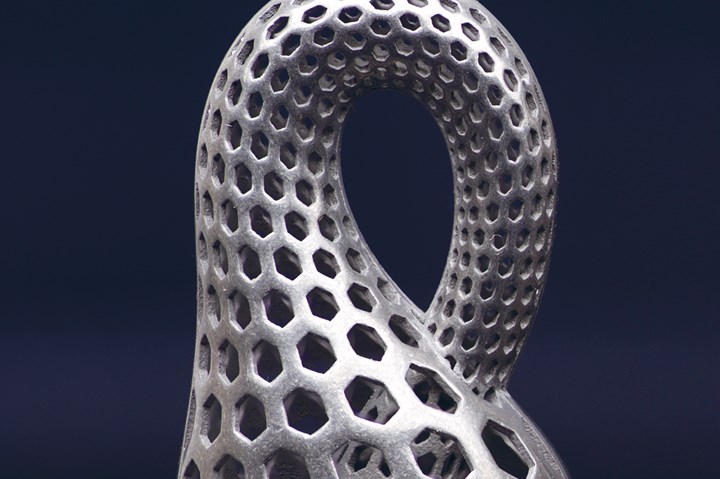

Photo Credit: Digital Metal

To meet the 3D metal printing market and its use of binder jetting technology—which uses an industrial printhead to selectively deposits a liquid binding agent onto a thin layer of powder particles—Digital Metal has expanded its portfolio to include DM D2, a tool steel alloy that is said to provide an effective combination of abrasive wear resistance and toughness. DM D2 is suitable for a wide range of applications, but most commonly for cutting and deformation tools.

According to Digital Metal, DM D2 is a versatile high-carbon, high-chromium D2 tool steel alloy that can be heat treated to high hardness and compressive strength. Hard enough to suit the task of stamping and forming other metals without losing its shape, it offers high wear resistance and is suitable in cold work applications that require sharp edges and abrasion resistance.

The steel alloy also delivers excellent surface finish and flexibility. The company adds that it is very stable during heat treatments, which allows for tailoring of the final material properties through various heat treatments after sintering.

Related Content

-

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

A 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.