Agemaspark Purchases 3D Metal Printing Machine, Improves Efficiency of Mold Tool

The EOS 290 enables manufacturing of mold tools through a conformal cooling technique to produce laser-sintered inserts. The technique improves efficiency of a mold tool by as much as 20%.

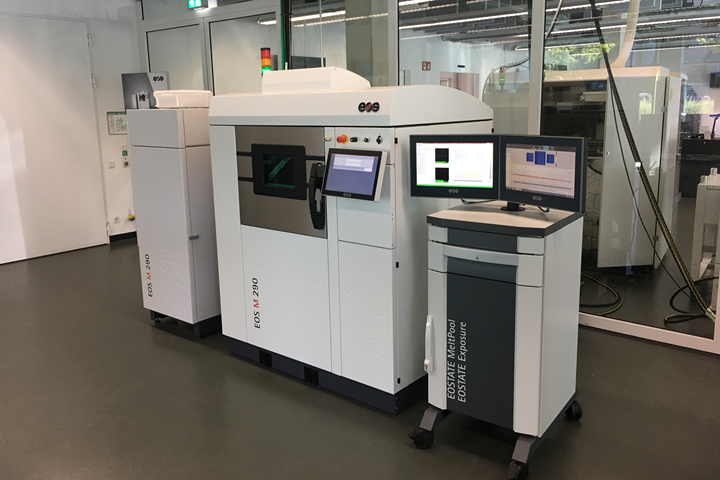

EOS 290 3D metal printing machine. Photo Credit: Agemaspark

Agemaspark Ltd., a specialist precision-engineering company established in Doncaster, U.K., in 2002, reported that it has recently secured finances to purchase a new additive manufacturing 3D metal printing machine, the EOS 290. The machine, says Agemaspark, enables the creation of innovative mold tools by developing a highly efficient advanced manufacturing process through a conformal cooling technique to produce laser-sintered inserts for mold tools.

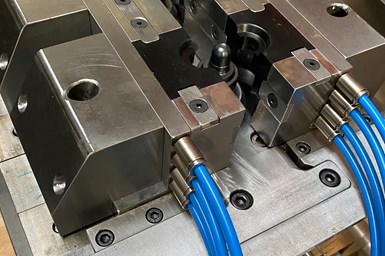

Additionally, after two years of in-depth research, and the production of a test mold to demonstrate the advantages of conformal cooling, Agemaspark adds that it has developed a technique that can improve the efficiency of a mold tool by as much as 20%. The research has enabled for tool sizes to be reduced by half as a result of the design of the inserts, which were deliberately created without large, drilled cooling channels. In addition to the introduction of conformal cooling, the company has added a further element to the molds by coating the inserts in ceramic to increase surface hardness, therefore reducing maintenance time and wear, giving Agemaspark the opportunity to have a more eco-friendly and efficient process to produce tooling for plastic components.

This reportedly ground-breaking process is said to offer new and more innovative ways to make intricate inserts that can be processed with cooling, which is currently not possible without using expensive heat transfer materials. With the introduction of its new in-house facility to produce inserts in a maraging steel with a hardness of 54 HRC, Agemaspark will soon be able to demonstrate the complete process to customers, with the machine becoming operational in January 2021.

Photo Credit: Agemaspark

One of Agemaspark’s main target sectors, the plastic caps and closures (multi-impressions components) market, continues to grow extensively in both the European and global markets, the company says. However, this relies on the mold tool manufacturing sector to keep abreast with new technology and speed of production. With the capabilities the EOS 290 provides, Agemaspark will become part of the global mold tool manufacturing stage, allowing the company to efficiently compete in creating innovative mold tools for the plastic component market, overcoming a number of industry challenges.

“This is a fantastic boost for the company and the local economy enabling Agemaspark to invest in jobs, reduce our environmental impact through waste reduction techniques and continue research and development efforts to penetrate further markets, in particular, the pharmaceutical sector,” says Paul Stockhill, managing director at Agemaspark. “We’re proud that we have the expertise within South Yorkshire, and ultimately, the U.K., to deliver these products, reducing reliance on external suppliers and imports and increasing competitiveness within the market as a whole.”

Agemaspark has a focus in precision engineering, CNC machinery, spark erosion and wire EDM with experience amongst a variety of sectors including aerospace, medical, oil and gas and plastic injection molding.

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.