WORKNC l Hexagon

46444 Hexagon Way

Novi, MI 48377 US

248-351-9300

worknc.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

WORKNC l Hexagon Supplies the Following Products

- CAD (Computer Aided Design)

- CAM (Computer Aided Manufacturing)

- CIM (Computer Integrated Manufacturing)

- CNC Software

- Data Management Software

- Data Translation Software

- Manufacturing Automation Software

- Mold Flow and Simulation Software

- Mold Quoting Software

- NC Simulation and Verification Software

Editorial, News, and Products

-

Access to CAD-to-CAM Workflow with Advanced Modeling Tools Accelerate Solid Model Preparation

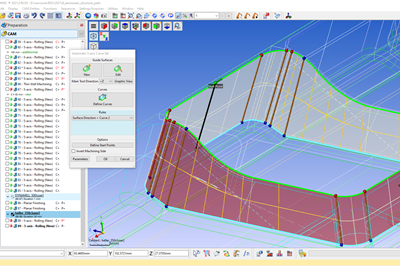

Hexagon is helping mold and die manufacturers improve their productivity by giving every WORKNC CAM software user access to its CAD-to-CAM workflow, Designer, to ensure that components are both feasible and optimized for efficient production.

-

Faster WORKNC Delivers on Performance

The Hexagon WORKNC 2021 software release offers faster toolpaths and a simpler user experience for improved productivity.

-

Hexagon Manufacturing Intelligence Hires Two Members

The Hexagon Manufacturing Intelligence Production Software Business has hired two new team members in support of its metal-cutting software.

-

Noteworthy News: Big Benefits

New websites, social media accounts, podcasts and modifications to packaging and materials to implement green initiatives from Mazak Corporation, The Plastek Group, WORKNC and Big Kaiser offer exciting benefits for customers.

-

Accu-Die & Mold Excels in Die Cast Tooling with a Focus on Service, Engineering, and Precision Manufacturing

Accu-Die’s highly trained workforce, well-equipped shop are key to meeting the challenging demands of die-cast mold production.

-

Noteworthy News: Growth Spurts

From new facilities dedicated to automation, training and distribution to new hires eager to tackle building relationships through providing excellent customer service, the industry innovators below are growing all across the United States, Canada and Mexico.

-

Latest WORKNC Makes Smart Factories Smarter

The latest release of WORKNC, from Hexagon’s Production Software portfolio, is said to make smart factories even smarter with new and enhanced functionality that addresses a number of manufacturing issues.

-

Hexagon Manufacturing Intelligence Production Software Business Hires Four New Members

Hexagon Manufacturing Intelligence Production Software Business has hired four new team members in support of its metal-cutting software.

-

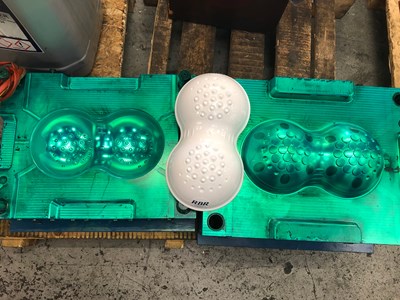

Extensive CAD/CAM Functionality Helps Complete Medical Mold Build in 6 Weeks

The industry has been talking a lot about automotive lately, so I thought I’d switch things up a bit and share the success of a medical device mold project attributed mainly to the right CAD/CAM with built-in mold component supplier catalogs.

-

Production Softwares Offer Significant Performance Boosts

The Hexagon Production Software business will present manufacturing solutions EdgeCAM, Radan, SurfCAM, WorkNC and NCSimul, designed to increase efficiency while ensuring quality, at SOUTHTEC 2019.

-

Hexagon Manufacturing Intelligence Appoints Global Marketing Director

Hexagon Manufacturing Intelligence has appointed Maja Foster as global marketing director of its production software business.

-

Makino Continues to Raise the Bar on Machining Technologies

Packed with information to help attendees advance moldmaking, and more, Makino’s Technology Expo shows the company’s commitment to its customers’ successes.

-

WORKNC to Feature at Makino Technology Expo

The WORKNC computer-aided-manufacturing (CAM) solution, which offers exclusive advanced toolform technology, will be exhibited September 10-12 at the Makino Technology Expo in Auburn Hills, Michigan.

-

Hexagon Hires Account Manager

The Hexagon Manufacturing Intelligence Production Software business hires new Account Manager Joseph Lopke to oversee accounts for its metal-cutting CAD/CAM customers in the Southeast.

-

Vero Software Hires Southwest Account Manager

Sean Arsenault joins Vero Software team to manage accounts for the company's metal-cutting solutions.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

Hexagon Hosts Vero Software Users' Meeting at HxGN LIVE 2018

Hexagon Manufacturing Intelligence hosts Vero Software Users’ Group meeting, a program designed for users and managers to master best practices, learn new features and realize user benefits. The event takes place June 12–15, 2018 in Las Vegas.

-

Software Launches New CAD-for-CAM and Robot Programming

WorkNC from Vero Software introduces two new tools to the portfolio—a direct modeling CAD system and a Robot Module.

-

Software Technology Is More Versatile, Efficient and Simplified

Software suppliers are working diligently to provide moldmakers with relevant but easy-to-use solutions that speed processes and lower costs.

-

Throwback Thursday: Software Advances Push Limits of Speed and Quality

This throwback article provides interesting perspectives on software for moldmaking while also illustrating how fast software technology moves today.

-

Moldmakers Choose Different Pathways to Workforce Development

Mold manufacturing companies share their strategies, the challenges they face and their commitment to training the next generation of makers.

-

Technology Showcase: On Display at EMO 2017

EMO is a large, international metalworking tradeshow with thousands of exhibitors. Check out the slideshow to see what will be on display!

-

Technology Showcase: Machining, AM and Software

With Amerimold in our rear-view mirror for the time being, there are still several new products that have been released, or will be soon, to bring to MMT readers’ attention.

-

Injection Mold Inc.

This shop specializes in rapid prototype molds and “quick-delivery” production molds.

-

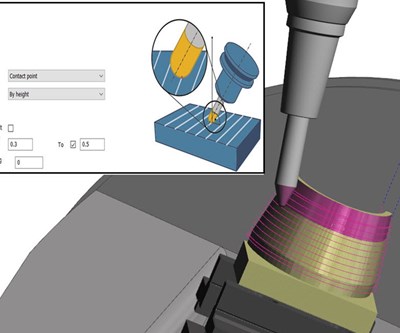

The Misunderstood Cutter Path

Normal vectors are not always the best choice for milling complex mold surfaces.

-

Software Advances Push Limits of Speed and Quality

Software for moldmaking continues to evolve as sophisticated features and capabilities are introduced, enabling mold manufacturers to produce the highest quality work in the most compressed leadtimes to date.

-

CAD/CAM Eases the Move to 5-Axis Machining for Moldmaker

Automotive moldmaker that handles molds up to 40 tons says Sescoi’s WorkNC helped ease its introduction to 5-axis machining with its effective global roughing strategies; smooth, powerful finishing; speed and ease; reduction in EDM operations; and, shop floor programming. Today it has four licenses, including two 5-axis for its machining applications.

-

How to Move Closer to Unattended, 24/7, Lights Out Machining

A look at why there is more to lights out machining than running unattended.

-

US Precision Mold Revolutionizes Its Job Management with the Right ERP Solution

Installing the MyWorkPLAN job management solution from the WorkPLAN range of ERP software solutions from Sescoi, was a monumental step forward for US Precision Mold (Arvada, CO).

-

Toolmaker Benefits from ERP Software

WorkPLAN Enterprise ERP software integrates with SAP® for greater transparency at German toolmaker HARTING Applied Technologies. The company has 15 WorkPLAN Enterprise workstations in a Citrix terminal server environment enabling managers, controllers, technicians and the sales personnel to have access to relevant data on the central WorkPLAN Enterprise system.

-

Five-Axis CAD/CAM Integration Helps Optimize Moldmaker’s Machine Utilization

Continual improvements to its business processes, coupled with aggressive training programs and investments in state-of-the-art 5-axis machining technology, has allowed Prospect Mold to bolster its success in the aerospace and automotive markets.

-

Four Steps to CAM Selection

Considerations when choosing the right CAM system solution for your mold build operation.

-

From the Field: Programming Software for Producing Playmobile Toy Molds

If it is still the norm in many tool- and moldmaking businesses to carry out programming either offline or directly on the machine, then the Playmobil example shows that a combination of both provides a lot of scope for creating and implementing new ideas.

-

Commercial Tool & Die: High Quality and Employee Innovation Drive Success

Unique, employee-developed programs tighten this moldmaker’s leadtimes—resulting in high quality tools delivered on time and the MoldMaking Technology 2008 Leadtime Leader Award: Large Shop.

-

Automation and Moldmaking: Streamling Processes

Automation is coming into the forefront as moldmakers are on the hunt to automate with software and equipment to streamline processes for optimal productivity—and quality.

-

Challenges to Five-Axis Machining for Moldmaking

When considering five-axis machining you must consider your goal for using five-axis machining on molds: to machine the complete part with the shortest cutters possible.

-

Shop Management Systems Add Value to the Mold Build Process

A new wave of job shop management system tools can help ensure more efficient mold manufacture.

-

How to Choose the Right CAM System

There is a wide range of aspects that moldmakers must consider before purchasing a CAM system.

.jpg;maxWidth=300;quality=90)