Faster WORKNC Delivers on Performance

The Hexagon WORKNC 2021 software release offers faster toolpaths and a simpler user experience for improved productivity.

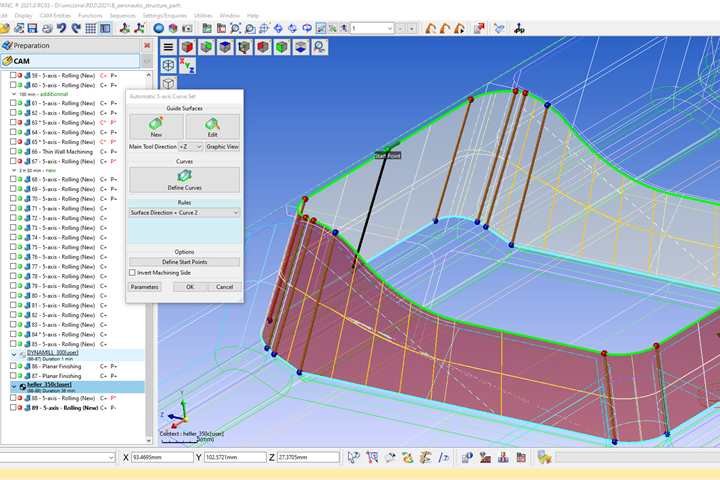

WORKNC 2021 5-axis curve set creation. Photo Credit: Hexagon

Hexagon has released WORKNC 2021, a software which delivers faster toolpath calculation for greater overall productivity, in addition to several other enhancements.

An enhanced Parallel Finishing toolpath in WORKNC 2021 enables manufacturers to use high-speed cutters of any shape, especially circle-segment tools such as barrel, lens and oval cutters. According to Hexagon’s figures, this strategy is now on average twice as fast as the previous equivalents, Planar Finishing and Z-Level finishing. In certain projects, the calculation time difference was four times faster.

Another important feature in the software release is the New Part centering/probing function, which generates PointSet nodes for any inspection machine or direct CNC part inspection on a milling machine. Additionally, a new Probe Inspect command creates and exports control points in the CAM project to feed a probing system. Specific improvements to part centering have been added, tailored for CNC machines with table palletization.

WORKNC builds on the fully-automatic, 5-axis curve creation by splitting the steps when more complex curves are required. It also enhances the synchronization capabilities between each curve’s bottom and top limits.

Improvements to corner finishing with 5-axis rolling include being able to improve surface quality by using a cutting tool’s larger circle segment. The 5-axis strategy can now change the contact point on the tool, ensuring optimal corner finishing with the tip of an oval tool.

A new strategy, 5-Axis ISO Guiding, guides the toolpath by curves and by an underlying drive surface. It supports profiled cutters with advanced toolform technology, and new 5-axis blade finishing functionality allows profile cutter management based on new algorithms.

New functionality in WORKNC Designer—the specialist CAD-for-CAM 3D modeling module—include eight dedicated advanced analysis functions for interrogating, analyzing and validating CAD models: Compare, Draft Analysis, Edge Analysis, Altitude Analysis, Curvature Analysis, Face area Analysis, Thickness and Face type.

Finally, WORKNC Designer’s Reverse Engineering module allows imported scan data, either from files or directly by connecting to Hexagon scanners, to be converted into a refined mesh. The mesh data can then be used as it is, or as a reference for curve and surface creation, enabling mesh models to be fully reverse engineered to complete CAD or convergent models.

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.