How to Choose the Right CAM System

There is a wide range of aspects that moldmakers must consider before purchasing a CAM system.

Often, people feel as though picking the right CAM system for their company is as difficult as picking the right anniversary present for a spouse. Sometimes one rushes in and picks the first thing they see, and it is not completely satisfying. Other times much thought, investigation and deliberation goes into the decision, and it can be quite satisfying.

When choosing a CAM system, there are different things to consider. This article is meant to highlight some of the items to consider when picking out CAM systems.

Consider Your Strategy

CAM software is available in three different strategic configurations.

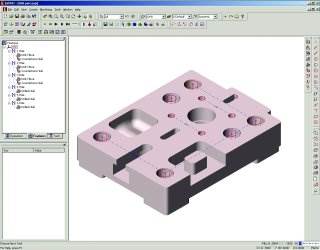

1. Full CAD/CAM packages. This is where the CAD is fully featured from dimensioning, plotting, bill of materials, modeling, data management, assemblies and more through manufacturing. Often the software is sold as modules. These systems are often sold as CAD systems, with CAM as an additional module. Some examples of full CAD/CAM systems are CatiaT by Dassault and UnigraphicsT.

2. CAM packages with some CAD capabilities are the next configuration. These are CAM systems that are capable of many CAD functions necessary for manufacture. These systems may have the ability to create and edit wireframe, surface and solid models - but may not have all of the advanced design tools available in a full CAD/CAM package. Some examples of these systems would be MasterCAMT or SurfCAMT.

3. CAM only packages have a precision focus only on CAM. Their software only creates cutterpath and has only minimalist design functions, such as the creation of boundaries. Some examples of CAM only packages are WorkNCT and Visual MillT.

Which configuration to choose is often debated. Some companies wish the convenience and integration of one CAD/CAM system. Others prefer the ease of use of a CAM only package.

The quick tip here is to purchase the system(s) that will maximize your profits and efficiency. Try not to remain rigid to one type of strategy, but be open to all possibilities.

Consider the Seller

CAM software is generally sold two different ways. It can be sold through a dealer channel or sold directly from the manufacturer. In some instances, software licenses are sold through both direct and dealer means.

Dealer channels allow for the sales and support team to be located closer to the customer geographically. This often means that the support, when needed, is closer to home. However, many dealers will carry different products. With some CAD/CAM resellers, the CAM portion can be a small percentage of their business. As such, they may not have the necessary experience to fully support it. It is important to find out the following from a dealer that you are thinking about purchasing CAM software from:

- How long have they carried that CAM product?

- How many support people are on staff that are trained in the program?

- What percentage is CAM to their entire business?

- How much training do they receive regularly from the manufacturer?

Typically, it is a good sign if the dealer has a milling machine of their own for experience and testing purposes. This shows an investment and commitment to CAM sales and support.

Purchasing software direct from the manufacturer may eliminate the "middle man," but it also may eliminate a close contact. Whether purchasing direct or from a dealer, one should inquire about the size and financial strength of the development company, finding out:

- How long has the developer been in business?

- How large is the development staff? Remember, if the developer makes several different products, that will spread resources thinner.

The quick tip here is not whether to purchase from a dealer or direct, but to purchase from a company that is knowledgeable in the product and will offer excellent support. Truly, the Internet and e-mail has brought support closer to the end user than ever before.

One question that many people have is whether or not they can purchase software used from another shop. Most software companies - not just CAM companies - are selling a license to use the software. Generally these licenses are non-transferable, and in most instances you will need written permission from the software manufacturer to transfer a software license. Find out for sure that the license can be transferred before making any decisions.

Determine the Types of Parts You Will Be Milling

Once the types of parts that are being milled are determined, this information can be used to narrow down a product range. Most CAM milling packages fall into different categories of functionality, often dictated by the type of milling being performed.

- Drilling - hole boring, gun drill and coolant lines - typically uses canned cycles on your mill controller.

- Two-axis milling - where the CNC mill moves simultaneously in the X and Y directions but not in Z. Simple contouring and pocketing are offered here.

- Three-axis contouring - this can range from small, fairly simple pieces like the mold for a computer mouse to a very complex mold like an instrument panel dashboard of an automobile. Typically the mill will move in X, Y and Z simultaneously. This form of milling is the bread and butter of moldmaking, as the majority of plastic parts have some form of contoured shape to them.

- Five-axis milling - where the machine has some form of rotation ability - typically A, B and/or C - on top of the regular axis movements. If the rotations happen concurrently with the axis (XYZ) movements, it is referred to as simultaneous five-axis. If the part rotates into position, then mills in three-axis, it is referred to as positional five-axis.

- Also, one may need CAM functionality for non-milling machines such as lathes, wire EDM or laser cutters.

Different CAM companies will be stronger at some types of milling than others. You must determine which type of milling will be the most critical to your business, and concentrate on those CAM packages that fill those needs. Ask the salesperson what the strengths and weaknesses of the CAM package are, and explain to him or her the types of parts to be milled. Often the CAM salesperson won't want to waste his or her time on a bad fit any more than the buyer wants his or her time wasted.

Secondly, you also must consider future growth plans. It is not uncommon for companies to take on more complex data and milling as their skill level and experience increases. Although you may start by milling only simple prismatic 3-D parts, you may grow into milling very complex 3-D data. CAM packages should allow a growth plan for milling the most difficult of parts.

Two common mistakes of CAM purchase decisions are buying too little software for your needs, or buying too much. If you buy too little, later you typically are forced to upgrade to a different package. If you buy too much, you may overpay and not use a majority of the features you spent money for. One common way that someone may buy too much is purchasing five-axis simultaneous software when it turns out that five-axis positional is faster, easier and less expensive and cuts the parts just as well.

Determine the Types of Data to Mill

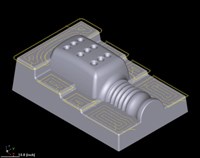

When milling molds, there typically are different types of data that get milled. The simplest is 2-D wireframe data, followed by 3-D wireframe data, solid models, surface models and other specialized data such as scan data or point clouds. Often the types of data that you expect to mill will narrow down the CAM choices available.

Make sure that the prospective CAM system is capable of reliably reading in the data to be milled. If using an integrated CAD/CAM system, typically the data is drawn in the same environment. However, since many shops mill data given to them from another company and usually a different CAD system, you must consider the translators available. Many different options are available for reading in data formats such as DXF, IGES, STEP, STL, ACIS solids and Parasolids. When considering translators, think quality over quantity. It is better to have a few really strong translators than several weak ones. When evaluating CAM systems, make sure to import several different files and check their validity.

Determine in What Environment to Mill

From shop to shop, it is common to find CAM software being operated in different locations and in different processes. You should determine where the software will be operated and by which employees. Three common locations for CAM software operation are: the CAD department, the CAM department and the shop floor. Operation of the milling software within the CAD department allows for one engineering function within an organization to be responsible for design and manufacture. Depending on workload, this option may reduce the number of software licenses and computers needed. Also, since CAD operators are already computer literate, they typically learn the CAM software quickly. Often in this structure you will see the complete CAD/CAM system being used.

The downside risk to the CAD department strategy is that many CAD designers are not experienced with actual milling operations. Additionally, frequent interruptions from the milling department to the CAD department can disrupt design productivity. Lastly, in a busy environment, the computer license can be "tied up" with CAD operations and unavailable for CAM.

Companies that use a separate CAM department generally use it as an interface between the CAD designers and the shop floor milling machines. CAM departments get the data files from the CAD department and create cutterpath for the shop floor to run. Often the persons running CAM software are promoted from the shop floor, and are thus well experienced. In this environment you can find all three types of systems: complete CAD/CAM, CAM with some CAD and CAM only.

The disadvantages of using a CAM department are that it is an extra step in the process, logistically. CAM operators can be interrupted by both the CAD department and the shop floor with questions and changes.

Faster personal computers with lower prices and easy-to-use CAM software packages have allowed many businesses to place the CAM programming right on the shop floor. This allows the person who is most familiar with the milling machine and tooling to create their own cutterpath. This strategy allows for fewer interruptions of either department and generally allows for shorter leadtimes. Disadvantages of this method are that additional licenses and training may be required for the amount of work. Shop floor programming makes great use of CAM-only software programs.

Make Sure You Go for a Test Drive

This is the most important portion of choosing a CAM system. Perform an evaluation of the system and actually cut metal on the milling machines. Evaluating software on your own data, on your own schedule and with your own mills will help you to determine whether the whole package and process will work or not.

During the evaluation, call the technical support people and see how quickly you talk to a real person - and how well they answer your question. Time how quickly the software creates its cutterpath, and how efficiently it runs on your mills. If running complex 3-D parts, check the surface finish on the finished part. Measure it to make sure that it is within necessary tolerances.

Conclusion

Following are some general points in regards to choosing a CAM package.

It is better to have two packages that are the best at what they do, rather than one that minimally meets either. Do not get hung up on one integrated package if two separate packages are more cost efficient in the long run.

Pick easier to use programs over more complex ones when you can. This makes training your employees much easier, and expands the scope of which employees can use it.

Make sure that the data translators you would use the most work without fail.

Make sure that the software is completely reliable - extra bells and whistles do you no good if it gouges your parts.

Evaluate the software on your data - with your mills on your schedule. Make sure that it will work for your parts.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

Choosing the Right Knowledge-Based CAD/CAM System

CAD/CAM systems that offer knowledge-based machining deliver tremendous savings in both time and costs, but only when the system meets your specific needs.

Read MoreFive Reasons to Work with Integrated CAD/CAM Software

Nowadays, we hear a lot about integrated CAD/CAM packages and many people wonder whether or not they should buy an integrated package or separate CAD and CAM packages. Here are just some of the reasons why it makes more sense to work with an integrated CAD/CAM package.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)