US Precision Mold Revolutionizes Its Job Management with the Right ERP Solution

Installing the MyWorkPLAN job management solution from the WorkPLAN range of ERP software solutions from Sescoi, was a monumental step forward for US Precision Mold (Arvada, CO).

Installing the MyWorkPLAN job management solution from the WorkPLAN range of ERP software solutions from Sescoi, was a monumental step forward for US Precision Mold (Arvada, CO). The company employs 13 people and specializes in molds for plastics, rubber, die cast and metal injection, producing new tooling as well as offering a repair and refurbishment service for existing molds. US Precision Mold can handle any level complexity and critical tolerance tools that your company needs to have built, including small and large medical devices, automotive, plus a wide variety of industrial and consumer products.

Darryl Lawrence, one of the co-owners of US Precision Mold, is responsible for preparing quotations and specifying the design of tools. When the company started, it used Microsoft ProjectTM and ExcelTM, together with other software packages, to manage its office based systems, but as the company grew he realized that this was a very inefficient way of working. “With our old systems we had to enter the data for each job at least four times, which is wasted effort and a potential source of errors. Furthermore, we carry out a lot of service work, which generates a good deal of paperwork, and we were getting to the stage when we would have had to hire someone just to keep up.”

Darryl Lawrence had some experience of job management systems and found the WorkPLAN site via Google. He looked at several systems but was impressed by Sescoi’s knowledge of the moldmaking industry, the world renown of its WorkNC CADCAM software and the stability of the company. “Other software providers had little knowledge of our industry but said they could alter their systems to suit us. MyWorkPLAN, on the other hand, was designed for our environment which was a big plus for us. Additionally, the cost verses benefit was very attractive, as what you get for the money is pretty good stuff!”.

US Precision Mold now takes for granted the flexible architecture in MyWorkPLAN. Darryl Lawrence says, “The software is very powerful for a small prototype environment. We can add as much or as little detail as we want, as the software assumes we know what we are doing. Other software forces you to do things a certain way which slows up the administration, leaving you with a very expensive drain on resources which actually slows up management processes.” He continues, “The reality is that, as a small company, there are a lot of things we should do which we don’t. With MyWorkPLAN there are templates for all these things already in the software. With this subtle approach we can look critically at the way in which we work and implement extra methodology when it suits us.”

The company has five user licenses of MyWorkPLAN located on PCs around its offices and workshop. It uses these for logging on and off tasks and for staff to clock in and out, enabling real time tracking of what is happening on the shop floor, managing time and attendance, and payroll, which can be completed in 45 minutes.

Darryl Lawrence says, “We use the software to drill down through the data to produce accurate quotations for our customers, control costs and manage shop loading and planning. Scheduling is a continuous and dynamic process, and MyWorkPLAN presents the information as a Gantt chart. We can place all our operations, look at the load and manipulate it until it looks right. We can’t plan much more than two weeks ahead anyway, as jobs and tasks are continually changing. The software lets us work in the way which suits us best, using our skills to get the load realistic by making changes such as adding time, moving operations or subcontracting.” Now US Precision Mold can respond to customer’s questions about the status of their jobs quickly and accurately. All bought in items have a specified delivery date, and it is easy to find out how far manufacture has progressed by just making an enquiry on MyWorkPLAN.

Darryl makes maximum use of Sescoi’s support, helping him to create customized reports so that he can extract a summary of just the information he wants. “I just make a phone call to Sescoi, and a week later I have my new report, which might be a summary of people and hours for each job, for example. In my view you are not going to get better support anywhere, period. The beauty of the software is that it is easy to use and it works - no bugs - you never have to worry about it crashing or doing something odd. If there is an error I can guarantee it is me that has made the mistake.”

He concludes, “MyWorkPLAN is a monumental step forward for us. You can’t afford to hire more people nowadays and the cost verses benefit it produces is a no brainer. It has made our life so much better and is a vital part of our business. Nobody wants to go back to the old methods. In my opinion we couldn’t have made a better choice and it is silliness not to invest in the technology.”

Related Content

Take Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreTolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreRead Next

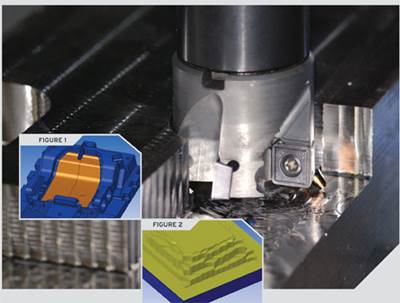

Practical Solutions To Common Machining Problems

Matching the roughing algorithm and tooling to the milling machine being used to machine the part is critical for high productivity.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More