Valve Gate Nozzle Enhances Direct Side Gating Capabilities

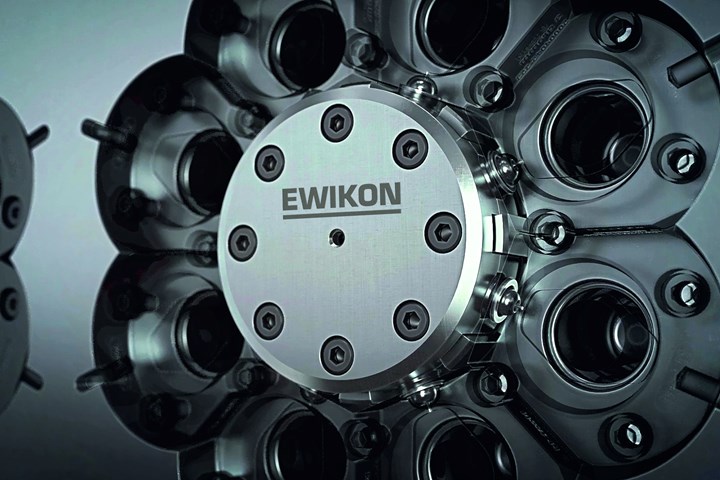

NPE2024: Ewikon is introducing the pro Edge VG range which sets new benchmarks in terms of ease of maintenance, gate quality and flexible use.

Through pro Edge VG, Ewikon is expanding its range of nozzles for direct side gating, with a valve gate version that sets new benchmarks in terms of ease of maintenance, gate quality and flexible use.

A key feature of the novel pro Edge VG nozzle is its easy maintenance, which adds to the high level of user-friendliness already offered by Ewikon’s open versions for side gating. All wear parts, such as the valve pin, valve pin guide and valve pin seal, are integrated into one assembly for each gate. This can be changed directly on the injection molding machine from the parting line without having to dismantle the mold. Downtime for routine maintenance can therefore be significantly reduced.

For demanding applications, Ewikon’s valve gate technology improves the quality of the injection point, and enabling new injection point positioning options. Additionally, the gating can now be carried out on geometries in which side gating was previously not possible due to insufficient shear surfaces. In general, an area corresponding to the gate diameter of the valve pin is sufficient.

In addition to standard polyolefins processing, the new nozzle also enables reliable side gating of articles made from soft plastics such as TPE — previously something only possible to a limited extent with open side gating.

The pro Edge VG valve gate nozzle can be configured with up to eight tip inserts. The nozzle’s flow channel layout, combined with the naturally fully balanced Ewikon manifold technology, guarantees equal flow paths and therefore uniform filling of all cavities. The parts are arranged in a circle around the nozzle body. Since the mold inserts do not have to be split for the installation of the nozzle, greater mold stability can be achieved. At the same time, the integration of uniform cavity cooling is made possible.

A linear servomotor with advanced control technology ensures high-precision and synchronous actuation of the valve pins. The valve pin stroke and opening speed can be varied continuously and adapted to process requirements. Furthermore, the space-saving design of the drive mechanism enables minimal stack height.

Related Content

-

Localized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.