Compact Valve Gate For Small Injection Molding Machines

The Ewikon L2X-Mikro high-performance hot runner system can be integrated into all common mold sizes for injection mold machines.

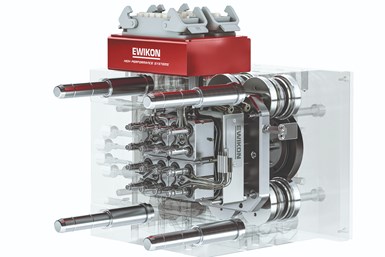

Four-drop L2X-Mikro valve gate system. All photo credit: Ewikon Molding Technologies

The Ewikon L2X-Mikro high-performance hot runner system for small injection molding machines is now available as a compact 4-drop version with valve gate technology for shot weights around 0.05 g per nozzle. The system uses synchronous plate technology for simultaneous actuation of all valve pins. Due to the very compact design of the drive technology, it can be easily integrated into all common mold sizes for small injection molding machines.

Sixteen-drop standard mold with 4 L2X-Mikro valve gate modules and standard synchronous plate.

The direct nozzle heating is said to guarantee a high thermal performance for reliable processing of standard materials and, above all, technical plastics with narrow process windows. The slim nozzles feature an outer diameter of 10 mm, a flow channel diameter of 3 mm and a leakproof screw connection with the manifold. Despite the compact design, it was possible to use coil heaters, which are integrated into precise cutouts in the melt-bearing pressure tube to enable a completely homogeneous temperature profile over the entire length of the nozzle. A special screw technology further enables the precise positioning of the connecting cables and minimizes the required installation space. The fully balanced manifolds have an edge length of 59 x 59 mm, reducing the overall flow path length and the melt volume to be exchanged in the system and ensuring problem-free processing of materials with critical residence times in applications with low shot weights.

The system is available as complete hot half in 4-drop version with a 30 x 30 mm pitch spacing. In order to realize higher-cavity systems, several of the 4-drop valve gate modules can be used in combination with a common synchronous plate and a bridge manifold resulting in a 16-drop, hot half with a mold size of 256 x 346 mm.

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.