Texturing, Engraving Service Supports Mold Builders, Plastics Industry

NPE2024: Custom Etch brings its knowledge in laser texturizing, engraving, marking and labeling to mold builders and molders via new technology investments.

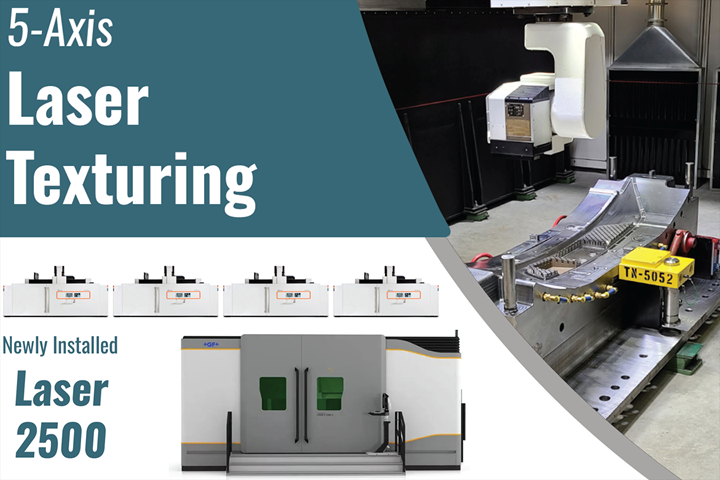

Custom Etch Inc. is a texturing and engraving specialist, with its core business servicing mold builders and the plastics industry. Considering itself as one of the larger five-axis laser job shops in the U.S. — more than 10 machine units are installed at its shop — Custom Etch strives to give customers the best turnaround time and pricing, keeping up with the constant evolution of laser technology and new hardware, which has been implemented to handle any shape and any size mold with high-speed 3D scanners with multiple laser sources.

Custom Etch produces texturizing, engraving, micro-structuring, marking and labeling of 2D geometries right through to complex 3D geometries. It also maintains capabilities for mold repairs, chemical texturing and offers a process to apply patterns to an extrusion roll.

The company recently increased capacity to meet high demand. In addition to its current lineup of technology, which it says will service any texture needs, Custom Etch invested in a Laser P 2500 U laser texturing machine from GF Machining Solutions, which offers increased accuracy and repeatability, reduced hot spots and other advantages, in addition to meeting Custom Etch’s requirements in terms of speed and size. This new unit was put into service and added to the company’s laser portfolio in January 2024.

Related Content

-

How to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.