Temperature Control Manifolds for Flexible Machine, Mold Tubing

Nonnenmann offers a wide range of mold temperature control solutions and expands the program with stainless steel manifolds for temperatures up to 392°F.

As a component supplier for the injection molding, die-casting and moldmaking industries, Nonnenmann Inc. offers practical and economical solutions for the flexible- and application-specific design of temperature control systems and hoses inherent to mold temperature control.

The company temperature control manifolds (series 117) provides a cost-effective and flexible option for machine and mold tubing. The manifolds are available in different variants and dimensions. Selectable outlets, lengths and thread sizes enable free design, depending on the requirements of the mold and the machine.

“Use of the temperature control manifold enables a simple, inexpensive and process-optimized solution for hosing,” Jochen Schwegler, technical advisor application engineering for temperature control technology at Nonnenmann, explains. “The manifold can be mounted close to the mold or next to the injection molding machine, so that the mold’s temperature control channels can be supplied with the temperature control medium in parallel using short hoses. This ensures uniform, optimum mold temperature control with minimal temperature deviations and the highest possible flow rate. From the temperature control unit or main water connection, the manifold is simply approached with a hose with a correspondingly large cross-section, which optimizes the flow rate.”

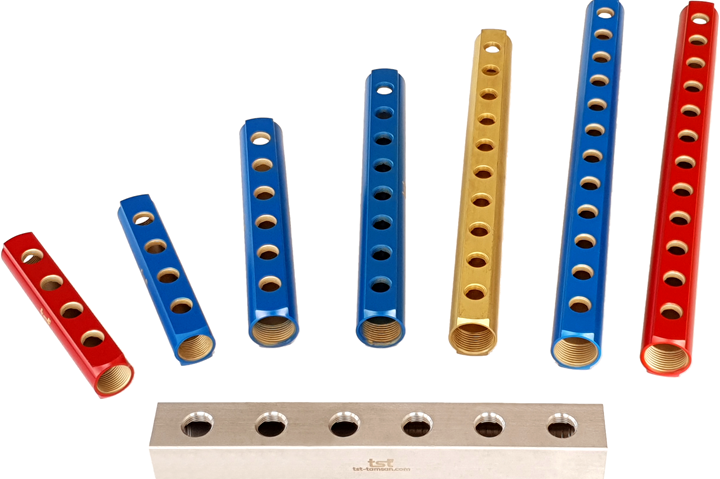

Depending on the application, project or requirements, a wide range of manifolds made of brass, aluminum (anodized) and stainless steel are available. Brass manifolds (Series 117-K) are designed for temperature control applications up to 284°F and a maximum of 16 bar; anodized aluminum manifolds (Series 117-KA) can be used up to 392°F and 16 bar. Each is available in red and blue, ensuring direct identification of flow and return. Depending on size required, customers can select connection threads from ¾" to 1¼". Manifolds are available from three-outlet to 16-outlet, each with threads from ¼" to ¾".

For high-temperature applications, the new stainless steel manifold (part no. FL9931) is said to be the ideal solution. The six-way manifold can be used at a maximum of 40 bar for temperatures up to 392°F. The temperature control medium is distributed from a 1" inlet to the six outlets, each with a ½" connection. Optionally available insulation encloses the manifold, increasing energy efficiency and work safety. The manifold works in combination with insulated Well-Flex hoses and couplings, which can be used up to 392°F, with corresponding seals suitable for these requirements, as well as fuses or flat-sealing leak-free valve.

In addition, in combination with the company's electronic flow meters, manifolds can be expanded into a digital temperature control manifold, enabling maximum process reliability; it can also be set up for temperatures up to 356°F.

Ultimately, the company says its temperature control manifolds create various application possibilities in practice and enable users to optimize the design of their temperature control system.

Additional accessory components are available through the Nonnenman portfolio.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success