Synergetic Enhances Mold Design Software Ease of Use

Amerimold exhibitor highlights new developments for its XMD mold design software to eliminate extensive training requirements for new users.

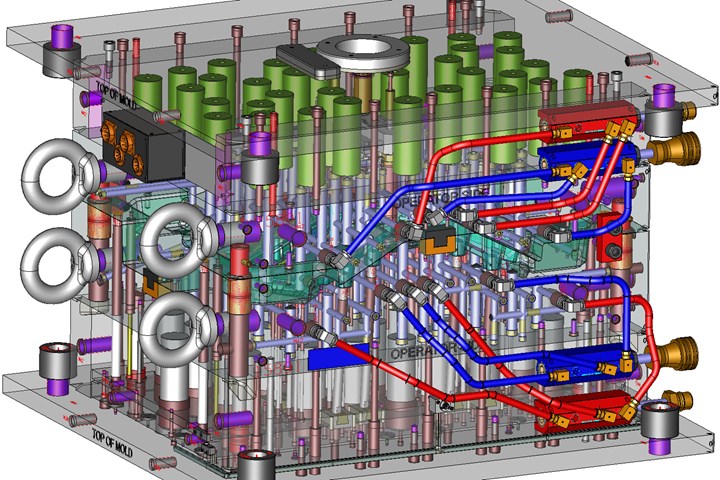

Photo Credit: Synergetic Eng & Manufacturing Services

Synergetic Eng & Manufacturing Services says its current focus in the development of XMD, an automated, knowledge-based mold design solution, is on ease of use. This has been achieved, the company notes, through the continuous leveraging of its intelligent automation technologies, with a conscious effort to afford all the advantages XMD offers to new users, and less experienced designers, such as eliminating extensive training requirements to be able to use the software.

New features have been added to XMD further demonstrate these objectives, including enhanced Relational Mold Base updates, and completely re-engineered Scope controls for precision control of changes. The company also notes several new products launching within XMD with the XPM - Expert Part Manager, XHR - Expert Hot Runner and several others.

Overall, XMD draws, manages, understands and checks hundreds of mold design details and has been developed to further increase the efficiency and accuracy of the design and manufacturing process.

The company will be showcasing XMD and its other solutions at Amerimold 2021 in September.

Exhibitor: XMD - Expert Mold Designer - Synergetic Eng & Manufacturing Services

Booth 130 (P)

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.