Standardized Color Table Simplifies CAD Design

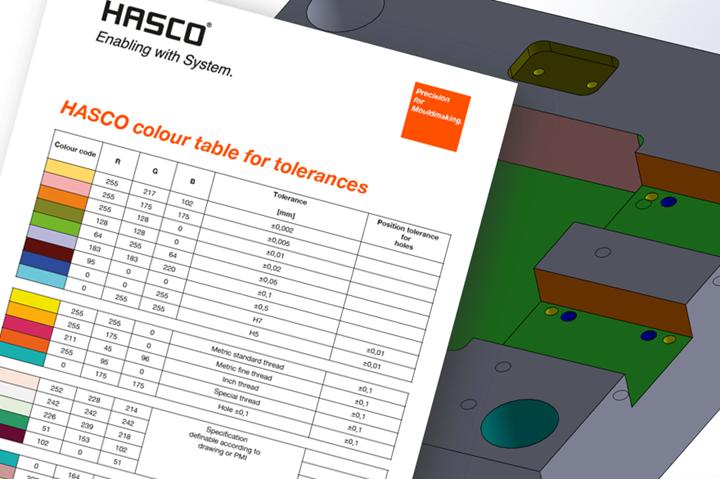

Color table developed by Hasco and partners more easily defines and derives workpiece tolerances in 3D CAD design and simplifies process automation.

Photo Credit: Haso America

Hasco America has worked with various cooperation partners to produce a standardized color table (VDWF Guideline 2020-1) for mold and toolmakers to easily identify workpiece tolerances in 3D CAD design. Conventional CAM systems used in production are able to recognize the clearly defined colors and automatically derive tolerances. The table is available on the Hasco website.

According to Hasco, misinterpretations can be effectively avoided when performing conversions from 2D drawings — the actual dimensions are automated through corresponding measuring systems and compared with the 3D model. This simplifies process automation. Furthermore, this tool can be used for easy exchange of models for production at other locations.

The standardized color table can be downloaded here.

Related Content

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

Technology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.