Open Software Technology Refines 3D Printing and Scanning Workflows

Siemen’s Parasolid geometric modeling software now offers tools for Convergent Modeling and lattice structures.

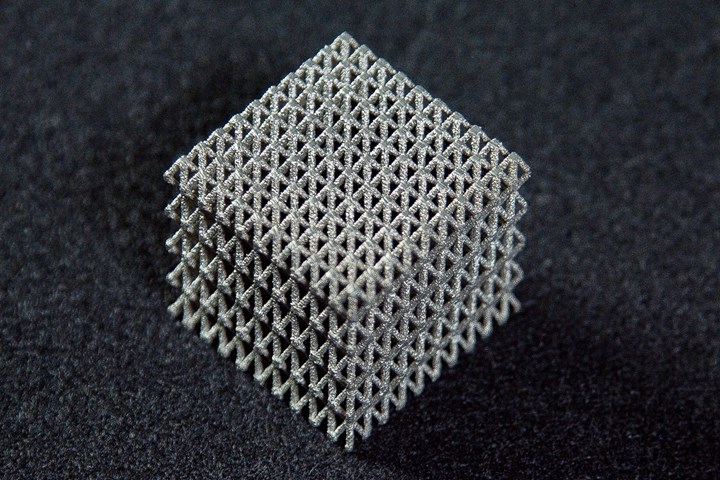

Photo Credit: Siemens Digital Industries Software

The release of Siemens Digital Industries Software’s Parasolid open software technology for geometric modeling is said to enable the solving of the most difficult technical challenges and improves upon 3D printing and scanning-based workflow with new tools for Convergent Modeling and lattice structures.

According to Siemens, the advances in Convergent Modeling provide engineers greater efficiency in workflows that need to mix facet and B-rep geometry. Further, the support of lattice structures—repeating networks of nodes and beams that offers increased strength-to-weight ratio while maintaining the required structural integrity—enables engineers to design parts with reduced material requirements and mass. Further, the functionality gives 3D printing a new level of accessibility and improved performance benefits.

Related Content

-

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.