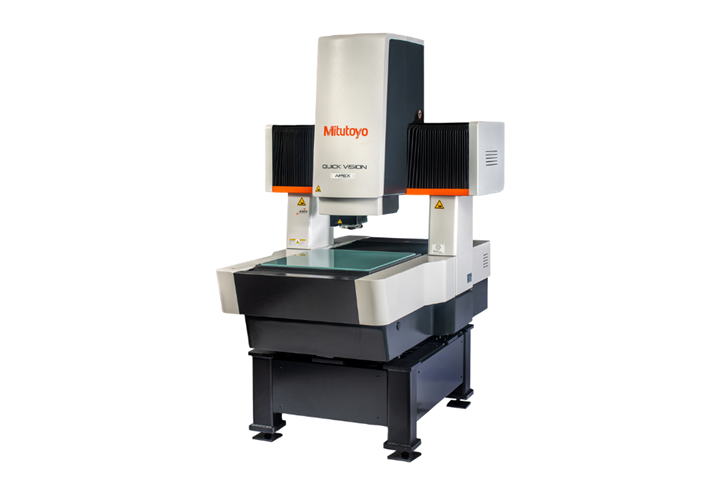

Noncontact Vision Measurement System Targets Accuracy, Throughput Needs Inherent to Mold Manufacturing

The Mitutoyo Quick Vision Pro Series speeds up run time, incorporates non-stop measurement capabilities and keeps the part in focus for mold and die applications.

Photo Credit: Mitutoyo America Corp.

Mitutoyo America Corp. announces the release of the Quick Vision (QV) Pro Series, the latest generation of Mitutoyo vision measurement systems that are ideal for 3D noncontact measurements of workpieces and high-throughput production, important features for maintaining the ultimate level of accuracy and repeatability using injection or die molds. The QV Pro Series in particular delivers more speed, efficiency and versatility to the company’s vision measurement line.

The QV Pro Series features a newly developed StrobeSnap vision measuring function that speeds up run time by approximately 35-45% regardless of measurement position or continuity while achieving higher throughput and high-precision measurements. Auto focus on the QV Pro Series is reported to be about 39% faster than previous models, without loss of accuracy.

An optional Stream function realizes very high throughput using non-stop measurements that synchronizes the main XY unit drive and strobe lighting. Stream takes images intermittently without stopping the stage and performs batch measurements at the same time, greatly improving measurement speeds, according to the company.

Optional Tracking Auto Focus (TAF) utilizes a laser tracker that will keep the part in focus while moving the joystick, eliminating the need to keep manually focusing on the part if it is not flat. When a part program is running, TAF keeps the part in focus, so the program does not have to stop for auto focus and stops potential errors from occurring if the part is out of focus. TAF cuts speed measurement times by approximately 30%, further improving throughput while maintaining high accuracy.

All the QV Pro Series machines can be retrofit with Stream capability, RGB (red, green, blue) illumination systems and side-mounted touch probe kits.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

-

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.