New Finishing Toolpaths Simplify Programming

Autodesk’s newly released PowerMill 2022 offers a range of improvements and new capabilities to optimize toolpath utilization and increase user simplification.

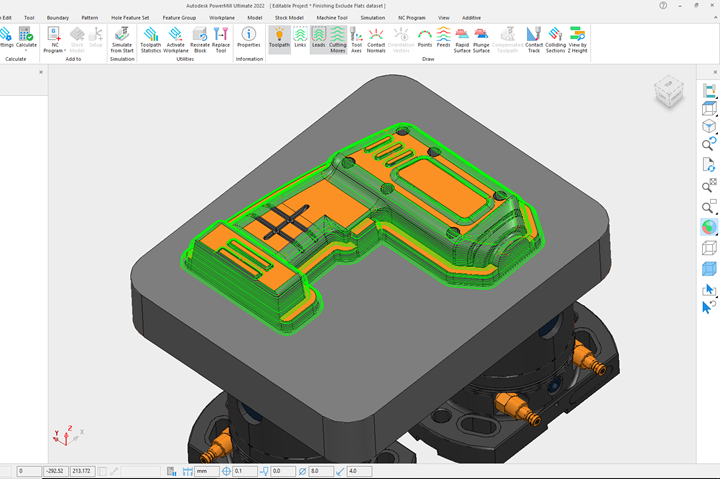

Photo Credit: Autodesk Inc.

PowerMill software from Autodesk is a 3D CAM solution that offers three- and five-axis programming tools for complex part production. Continuing the theme of previous releases, Autodesk says the new PowerMill 2022 release includes a range of improvements and new capabilities aiming for optimized performance and user simplification. New highlights include improvements made to some of the software’s most commonly used finishing toolpaths.

With the new release, Autodesk says finishing toolpaths, such as Steep & Shallow, Raster and 3D Offset Finishing, now have the option to automatically exclude planar faces during calculation. The company says this means programmers no longer need to spend time creating separate boundaries to limit the machining. Overall, the enhancement is said to enable faster CAM programming, faster cycle times and better cutting tool utilization.

Autodesk says PowerMill 2022 also has improved toolpath accuracy using the Flat Finishing toolpaths. The company says that, in previous releases of PowerMill, there were occasions where the toolpath could contain chamfers in internal corners. These small errors could result in material being left un-machined which would need to be removed later, either using additional toolpaths or by manual polishing. This latest release of PowerMill now produces more accurate toolpaths, reducing the risk of material being left un-machined and helping to avoid the need for manual polishing.

As the underlying code is used in other areas of PowerMill, such as the previously mentioned Steep & Shallow, Raster and 3D Offset finishing toolpaths, these and other features will also see improved accuracy.

Additional PowerMill 2022 highlights include:

- Constant Z finishing toolpath has been made more accurate to avoid incomplete or fragmented toolpath processing.

- Four-axis and Rotary finishing toolpaths, which now include the option to define clearance values that will be used to tilt the fourth axis of the machine to avoid collisions that might occur between the cutting tool assembly and the workpiece.

- New Project Ranges allow users to define the distance that the projection toolpath is allowed to project away from the reference surface being used.

- Staggered Start Points (which only applies to closed toolpath segments), a new feature that automatically moves the start position of toolpath segments to improve machine motion, resulting in a better surface finish.

Related Content

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.