Move Into Automation Adds to Mold Building Quality, Competitiveness

NPE2024: Cavalier Tool is showcasing its multiphase shift into more automated processes for lifters, inserts and slides manufacturing, in addition to giving attendees a chance to step inside a mold.

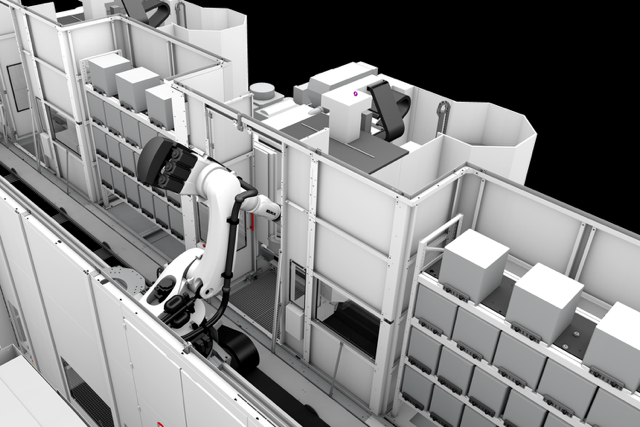

Source: Cavalier Tool & Manufacturing

Mold builder Cavalier Tool & Manufacturing has a decade-long history of continuous growth. To successfully navigate the obstacles inherent to this, the company has set its current focus on automation, to ensure it has good data to make decisions and measure results.

The Cavalier booth will be highlighting the company’s four pillars — focused on automation, toolmaking, people and a Virtual Reality setup pillar so trade show attendees can step inside a mold and see first-hand what the company has coined “The Cavalier Experience.” For the latter, Cavalier has worked with local Invest Windsor-Essex team to enable people to step inside a mold.

“We have a system that goes beyond building molds,” says Cavalier sales manager Peter Gossmann. “It starts with our design for manufacturing [DFM] team. Prospective customers can vet their part design to optimize conditions that produce the best possible mold.”

To build quality customer molds — ranging from injection, structural foam, gas-assist, multi-shot, thermoset, prototype or compression molds — Cavalier is currently operating an AI-driven robotic cell that consists of three five-axis machining centers, serviced by a multi-axis robot that draws from a 235-pallet library.

This is the third phase of Cavalier’s journey to repatriate all complex 3D components previously sourced LCC, which has been a decade-long multiphase investment. Expanding to include sinker and wire EDM processes, once the automation cell is finalized, the company says it will be able to manufacture lifters, inserts and slides completely without human intervention. From stock blanks to finished product, Cavalier anticipates the cell to take data from scheduling and blanks from the library and produce just-in-time components for its assembly department to drop into molds.

Ultimately, the growth into automation ensures that Cavalier can meet customer demands and remain globally competitive, but notes that “adding automation doesn’t necessarily mean we need fewer people. We still need skilled workers. In fact, as we look to the future, we need people with even more skills who are trained for jobs that don’t even exist yet.”

Related Content

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success