Maraging Stainless Steel Powder Engineered for Additive Manufacturing Applications

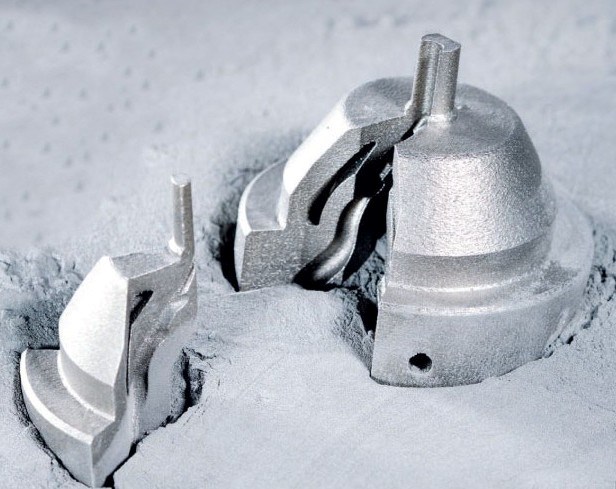

Bohler M789 AMPO, introduced by Edro Engineering, is well suited for conformal cooling inserts, or applications where high hardness and corrosion resistance is required.

Photo Credit: Edro Engineering and Specialty Steels LLC

Edro Engineering and Specialty Steels, an exclusive distributor of Bohler tool steels, highlights Bohler M789 AMPO, a newly developed maraging stainless steel powder designed for additive manufacturing (AM) applications.

Bohler M789 AMPO combines the mechanical properties of maraging 300 steel with the corrosion resistance of 17-4 PH stainless steel. Edro says the patented grade can be easily printed without preheating and can achieve a high hardness of 52 HRC with easy heat treatment. Bohler M789 AMPO also has excellent polishability which makes it the ideal choice for conformal cooling inserts in plastic injection molding and in any other application where high hardness and corrosion resistance is required.

For more information please visit Edro.com.

Related Content

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D-printed parts.

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.