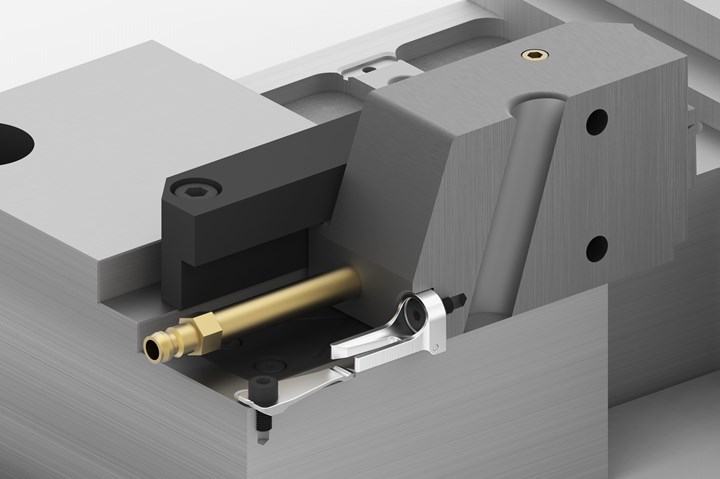

Leaf Spring Roll Stopper Locks In Slide Bodies' End Position

The Meusburger E 3050 leaf spring roll stopper offers two variations that enable retaining forces up to 140 N. Components guarantee minimal friction and no play.

All photo credit: Meusburger

A cost-effective alternative to existing slide retainer solutions, Meusburger’s E 3050 leaf spring roll stopper possesses a compact design which enables retaining forces up to 140 N, proving it ideal for holding large slide bodies in their end position. A wide range of applications are covered via two variations and three different leaf spring thicknesses.

The roll inside the roll holder locks under tension when the mold is opened. The leaf spring’s recess ensures that the slide body is held in a precise position without play. In addition, the freely mounted roll, made of bearing steel, and the nitride leaf spring ensure minimal friction for maximum service life. Meusburger slide retainer can be used at temperatures of up to 200°C.

Type A.

The leaf spring roll stopper’s Type A variation has an integrated stop that enables precise and secure positioning. In addition, an adjustable slide stroke with optional E 1312 spacer disc is available. The roll holder feature can be replaced without dismantling the slide.

Alternatively, the Type B variation enables similar adjustment of the roll’s height through the additionally available E 1312 shim to compensate for manufacturing tolerances. The flat installation space means that this version can also be used in confined spaces. An integrated screw can serve as a stopping mechanism.

Type B.

Leaf springs are available in three different thicknesses for maximum flexibility and interchangeability without rework. All components can be mounted or dismantled from the split line face without having to remove the mold. Meusburger recommends cleaning and then lubricating the roll after 100,000 cycles with the fully synthetic VLS 250 high-performance oil.

CAD data for mold design, including installation spaces, are immediately available for download. Slide stroke can also be configured individually within the limit values.

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.