Integrated Software Platform Adds Product Design, Simulation Extensions

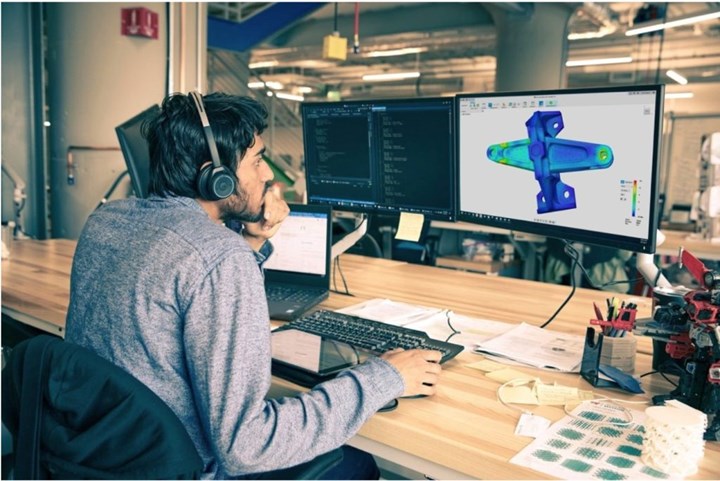

Autodesk’s Fusion 360 cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform now offers an injection molding simulation study type.

Photo Credit: Autodesk Inc.

Autodesk Inc. has made available the Production Design Extension and Simulation Extension, which have been added to Fusion 360, the company’s integrated 3D CAD, CAM, CAE and PCB software for product design and manufacturing. Initially highlighted during Autodesk University (AU) in 2021, these extensions improve the platform’s performance, user experience and efficiency.

The Product Design Extension, Autodesk says, extends the core 3D design and modeling capabilities of Fusion 360 with access to design tools that automate and simplify the creation of features that are natively aware of the manufacturing process. Users are able to create highly intelligent features that automatically update when the material changes, which in turn will save the users time. Access to geometric patterning tools, advanced volumetric lattice technology and more are also made available. With this model, customers can choose either daily access, monthly access or annual access.

The Simulation Extension enables the user to improve product performance in Fusion 360 with access to an assortment of simulation capabilities including structural, thermal, explicit and includes the new injection molding simulation study type covering:

- Non-linear static stress

- Event simulation

- Modal frequencies

- Injection molding simulation (moldfilling, part quality, guided results)

- Structural buckling

- Thermal steady state

- Thermal Stress Analysis

- Shape Optimization

Autodesk says this extension also allows users to subscribe for unlimited access for either a monthly or annual term, improving the experience and removing friction from the development process.

These two extensions are part of a slew of January 2022 updates and additions which you can learn more about here.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.