Inspection Manager Software Enhances Collaboration and Automation

High QA’s updated Inspection Manager (IM) software features next level Quality 4.0 standards, increased automation and enhanced workflows.

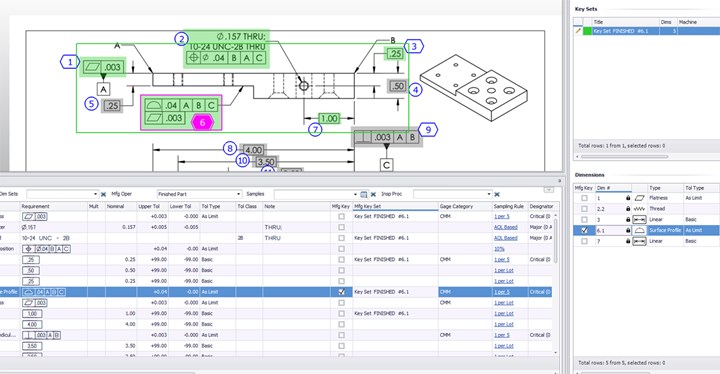

Image courtesy of High QA

High QA, a manufacturing quality management automation software provider, releases Version 5.1 of its Inspection Manager (IM) software, which features next level Quality 4.0 standards, increased automation and enhanced workflows.

Inspection Manager is a comprehensive database-driven solution for manufacturing quality management throughout the production and supply chain process. The centralized database contains manufacturing inspection plans, ballooned drawings, inspection results, first article inspection (FAI) and statistical process control (SPC) reporting and incorporates all quality requirements that enables accountability, traceability and repeatability. According to High QA, the streamlined quality inspection process eliminates paper documents, prevents human interpretation errors, standardizes best practices and increases efficiencies in collaboration and compliance on the shop floor.

Version 5.1 continues support for key industries and compliance standards including automotive (QS-9000/ISO/TS16949, APQP, AIAG guidance), medical (21CFR, ISO 13485), aerospace (AS9100/EN9100, AS9102), defense, heavy machinery, oil and energy and others with multiple best practice standards.

Inspection Manager Version 5.1 also delivers several enhancements to improve workflows, efficiency and traceability including in-depth AQL-based sample planning, a Manufacturing Key Sets feature, robust user access control and workflow and usability enhancements.

Integrated AQL-based sample planning provides a more efficient workflow with data and plans in one centralized database. It only requires setting up a sampling plan once and can be used across multiple jobs, lots and orders. According to High QA, modifications to the plan are simple to make and are immediately visible. Integrated AQL-based sample planning allows for repeatability, scalability and consistency. Inspection Manager sample planning is based on MIL-STD-105 and Z1.4 AQL standards and supports many other common AQL tables.

The new Manufacturing Key Sets feature enables workers to group dimensions by cutting tools the same way parts are made on the shop floor. Dimensions affected by the same cutting tool are added to a Manufacturing Key Set group and color-coded on the print for easy identification of each group. The most critical dimension in each Manufacturing Key Set is marked as a Key dimension and made identifiable on the ballooned print. When the Key dimension passes inspection, the remaining members of the Manufacturing Key Set are marked as passed. Manufacturing Key Sets is an integrated feature working together with AQL-based sample planning and the centralized database system to maintain the integrity of the Geometric Dimensioning and Tolerancing (GD&T) and inspection results data. The all-in-one system provides full, automated traceability to the source.

Further, control access is offered to sensitive part data with Inspection Manager’s integrated security control access system. Define security groups by location, department, role or individual user to restrict part record access based on a “need to know” or ITAR requirements. Users can be added or removed from access groups in a central location eliminating the need for the IT department to manage separate secure and unsecured servers.

Finally, additional enhancements to the software include the ability to see inspection status for a part showing completed, to be inspected and failed results. Each sample shows the inspector and time stamps for the first and last results increasing visibility and traceability across the lot/job. Real-time notifications and alerts are trigged for failed dimensions and lot acceptance status and can be configured for each part or job. Gage management automatically tracks detailed usage history for each gage with the ability to sort or filter gage usage by part, job, inspector, date range and more. Gage information is also accessible for detailed lookups.

An enhanced OCR (Optical Character Recognition) system captures a higher percentage of GD&T from poor quality drawings, adds new balloon shapes and arrows and incorporates a drag and drop feature for adding custom requirements if not found in the drawing.

Included with the new release are expanded materials, process management and template libraries.

All features benefit from the centralized database. A single information source for production and manufacturing data extracted from a drawing, inspection plans, inspection results and SPC information reduces the need for spreadsheets. The integrated database ensures data integrity and avoids misinterpretation of key data.

“This release is dedicated to supporting our community of customers by enhancing collaboration and automation between the manufacturing and quality process,” said Sam Golan, High QA CEO and Founder. “Inspection Manager continues to improve productivity and efficiency starting with the planning phase, through in-process and final inspection, inspection data collection, SPC data collection and reporting by at least 5-10 times. This release will further increase this productivity metric.”

Related Content

How to Automate Process and Design

Moldmakers can improve their operations and stop wasting time by taking these six steps for process and design automation.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreRead Next

Digital Solutions Service Suite Strengthens Industry 4.0 Manufacturing

The United Grinding Digital Solutions modular service suite features solutions including remote service, service monitor, production monitor, customer cockpit and IT security.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More