Gundrilling Machines Deliver Oerational flexibility

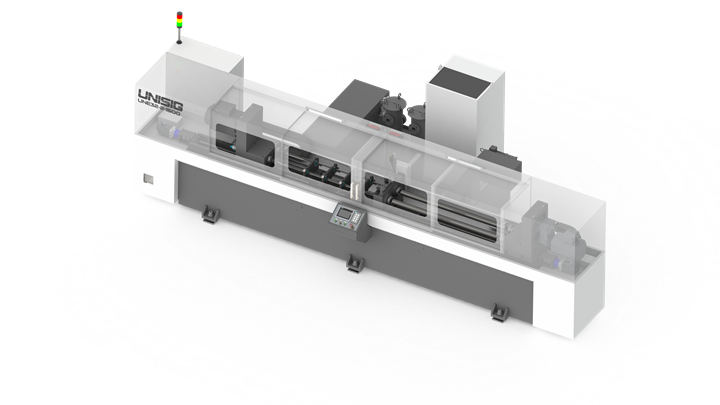

UNISIG’s next generation of UNE series gundrilling machines delivers operational flexibility, improved performance and effortless operation.

Ideal for manufacturers focused on high-volume/low-mix or low-volume/high-mix production environments, UNISIG’s next generation of UNE series gundrilling machines delivers operational flexibility, improved performance and effortless operation. The UNE Series is engineered and designed to simplify gundrilling for all those individuals involved in a facility’s manufacturing process. The UNE Series offers gundrilling solutions that are well-suited for various industries, including firearms, automotive, medical, energy, defense and aerospace.

With five models built from two frame sizes, the UNE Series can drill hole diameters from 1.4 mm to 40 mm and depths up to 3,000 mm. The compact frame construction saves valuable floor space as well. Each machine can fit in close proximity to a shop’s existing machining center, lathe or Swiss-style machine for efficient part-processing strategies. Built with quick and easy setup in mind, the machines are also small enough to be relocated when necessary. For added flexibility to grow with future production needs, all UNE models are robot-ready, allowing shops to add a robot whenever it fits into their budgets and production schedules.

The single main spindle servo motor delivers the necessary horsepower for two-spindle machines. When power is applied in single-spindle mode, however, shops can produce holes with larger diameters, increasing their capabilities and adding the potential for new business without adding a new machine.

The UNE Series features a programmable flow-based coolant delivery system designed to provide the right amount of coolant to the tool’s cutting edge. The end result for the operator means they can confidently predict tool breakage and spend less downtime recovering an interrupted process.

Powered by Siemens, UNE Series machines feature intuitive controls that give operators a full process picture at a glance on a rich color interface with touchscreen capabilities. Ergonomically designed and engineered with the building owner and operator in mind, UNE machines offer an automated door option, which can benefit companies with or without automation.

All UNE bases are FEA optimized and machined on five sides in single setup for the highest overall precision and simplified installation with no foundation work required.

Related Content

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.