Electric Servo Cylinder Enables Detailed Valve Pin Control, Energy Efficiency

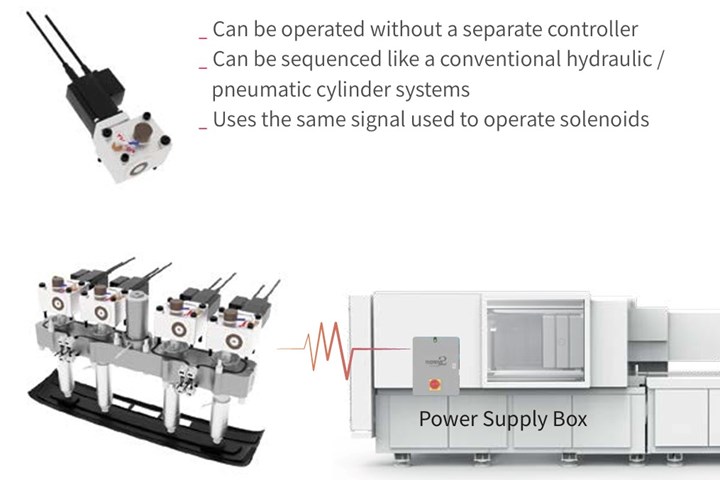

NPE2024: Yudo USA features Yu Drive II Eco, a compact solution that doesn’t require a separate controller, operating only by combining injection machine signals.

Yudo USA features the Yu Drive II Eco electric servo cylinder. Its electric valve pin control enables more delicate, individual control of the valve pins in a compact setting using only the signal from the injection molding machine, potentially solving a wide range of challenges that can occur during production.

Use of the Yu Drive II Eco reduces the cost of Capex due to the input signal that comes from the molding machine and eliminates the need for an external controller. Moreover, the solution has a finite amount of settings, making setup quick and easy. Seven total configurations are possible.

Yu Drive II Eco can be sequenced like conventional hydraulic/pneumatic cylinder systems. It uses the same 24 VDC signal used to operate solenoids. Importantly, Yu Drive II Eco consumes less energy than a typical hydraulic cylinder, adding to its more eco-friendly nature.

The company notes that sustainability has been a trend it continues to pursue, whether it’s through the electric servo cylinder, or hot runner systems and components that perform well with eco-friendly recycled resins. Yudo looks forward to working with customers on their new projects.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.