Digital Boring Head Program Offers Smaller Sizes

Head sizes down to the CKB1 modular tooling connection size are now offered by Big Kaiser. They will feature the same boring ranges and accept the same accessory products as their standard analog counterparts.

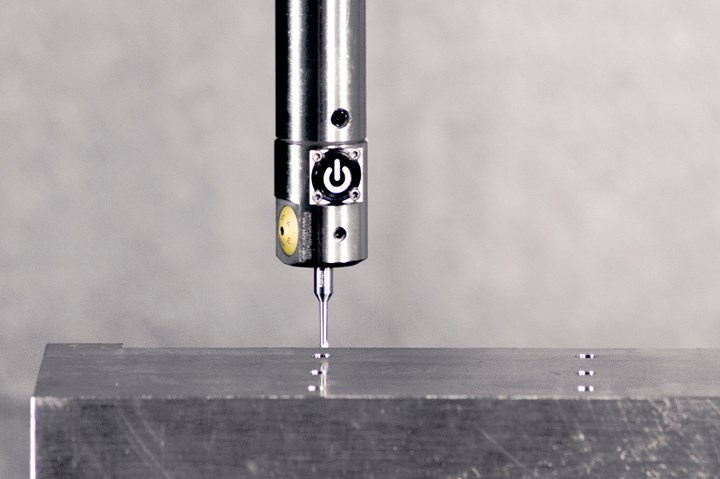

EWE digital boring head rgb. Photo Credit: Big Kaiser Precision Tooling Inc.

Big Kaiser Precision Tooling Inc. is expanding its offering of digital boring heads to include head sizes down to the CKB1 modular tooling connection size, which means boring down to Ø.787 in. for Series 310 peripheral heads, and Ø.016 in. for Series 112 centric boring heads.

The new heads will feature the same boring ranges and accept the same accessory products as their standard analog counterparts, ensuring an easy transition to digital tooling for all applications.

Due to the small sizes of these boring heads, the digital display will no longer be present on the head itself. Rather, the adjustment value will be shown on a separate mobile device or tablet that has the Big Kaiser app installed. Once connected to the head, the app can also be used to set the target diameter and tolerance. This information will stay assigned to the specific head connected until it is changed by the operator. Along with the last measured cut information (entered by the operator each time an adjustment needs to be made), Big Kaiser says the app can show the adjustment required to get the head set to the target diameter.

An optional handheld device that displays the incremental adjustment value is also available. According to the company, this is useful for shops that may not permit personal mobile device use on the shop floor. The unit has four push buttons for simple use—Enter/ON, Back/Disconnect/OFF, Scroll down (Tool Select, Metric/Inch), Display Reset—as well as a battery level indicator.

Related Content

-

How a Small Programming Change Cuts Cycle Time in Half

Overriding the CAM system when milling a series of lifter pockets helps to improve metal removal rate and increase feed rates.

-

How to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

-

How to Overcome Deep-Hole Drilling Obstacles in Mold Machining

Keep up with the newest tooling innovations to overcome holemaking and finishing challenges.

.png;maxWidth=300;quality=90)