CAM Software Enhances 3+2-Axis Toolpath Programming

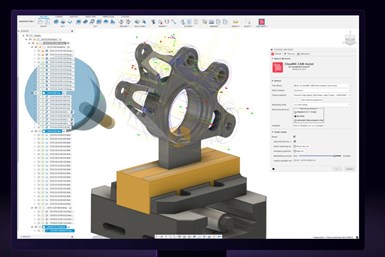

CloudCNC’s CAM Assist uses AI to generate intuitive machining strategies in minutes or seconds, depending on complexity.

CloudNC has announced that its CAM Assist solution can now create programming strategies and tool paths with AI for 3+2-axis CNC machines.

The new upgrade means CAM Assist can now provide strategies and tool paths for 3+2-axis components, enabling many more manufacturers to benefit from CAM Assist’s efficiency gains.

CAM Assist uses advanced computer science techniques and AI to generate intuitive machining strategies in minutes or seconds, depending on complexity, which could take CNC machine programmers hours or even days to manually create.

As a result, the amount of time it takes to program a CNC machine to make a component is greatly reduced, compared to the previous manual programming process, as is the time spent to estimate how much a new component will cost to program. This enables manufacturers using CAM Assist to raise productivity and shorten lead times, while also estimating for more work, more quickly. According to the company, CAM Assist can save an average workshop more than 300 hours of programming and estimating time per year.

CAM Assist is available for Autodesk Fusion today. CloudNC is currently undergoing beta testing in other packages, and expects to launch solutions for those later in 2024.

Related Content

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.