CAM Calculator Optimizes Part Cost, Cycle Time Computation

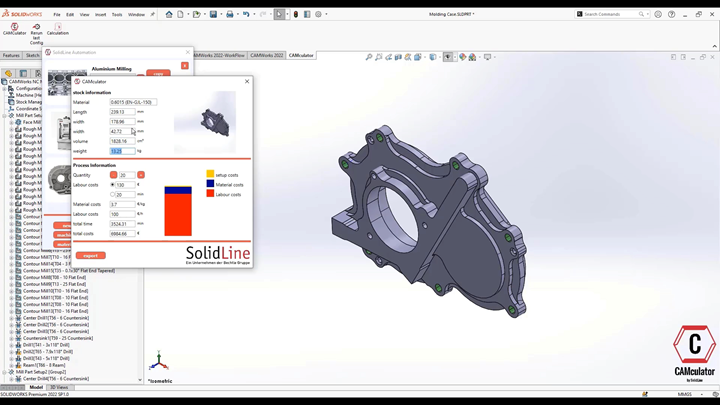

The Solidline CAMculator tool for moldmakers, offered through HCL Technologies at IMTS, automatically calculates the cost of an entire part using CAM model data.

German-based PLM systems company, Solidline GmbH, expands its CAM solution offerings to the U.S. through a partnership with HCL Technologies, the developer of the HCL CAMWorks programming solution available for machining centers, turning, mill/turn and wire EDM applications. The company releases Solidline CAMculator, a tool that can calculate cycle time used from CAM model data to ultimately program and calculate the cost of an entire component. Solidline CAMculator supports the automation and costing of parts for up to five-axis simultaneous machining.

Traditionally, costing is calculated using old stock, estimated values or trial programming. However, HCL Technologies notes, the use of data based on the actual NC code of a part enables companies to reduce calculation time and labor while also reportedly achieving repeated accuracy and company-wide consistency. This capability is key for moldmakers, the company adds.

Solidline address everything from consulting to installation, configuration, training and support to help achieve professional, reliable machining.

Related Content

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.