Aluminum Machining Efficiency Improved With Milling Inserts

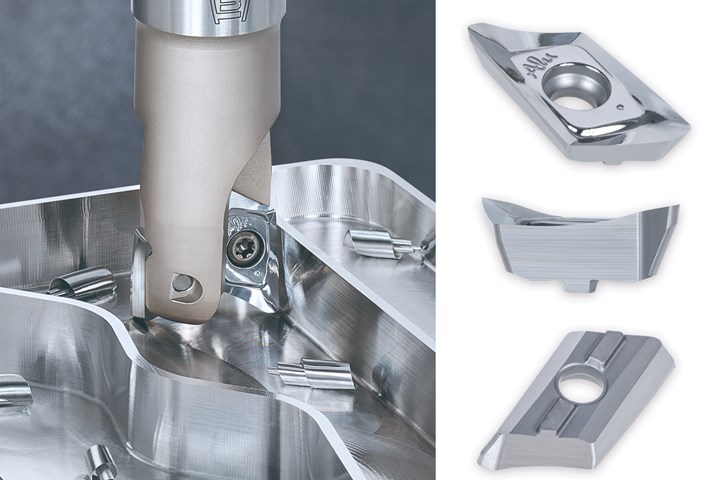

The TungAluMill line has been enhanced with 10 new XVCT-AM inserts, featuring an interface design that augments machining at high speed rates.

Tungaloy presents 10 new XVCT-AM square shoulder milling inserts to expand its TungAluMill line designed specifically for non-ferrous applications.

TungAluMill is intended for efficient machining of aluminum alloys and other non-ferrous materials at high speed rates. The tool is designed to eliminate radial insert displacement caused by heavy cutting forces and strong centrifugal forces during high-speed rotation of the cutter, which is essential for efficient machining of aluminum parts. Additionally, the insert’s top and peripheral surfaces are ground and polished to a mirror-like finish, resulting in high-positive and sharp cutting edges that ensure soft cutting action, good surface finishing quality and prevention of built-up edge formation on the cutting edge.

Based on the features of the company’s conventional XVCT-AJ inserts, the XVCT-AM inserts introduce an enhanced interface design that improves insert retention during high-speed machining while reducing raw material use for insert production, all without compromising cutting performance.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)