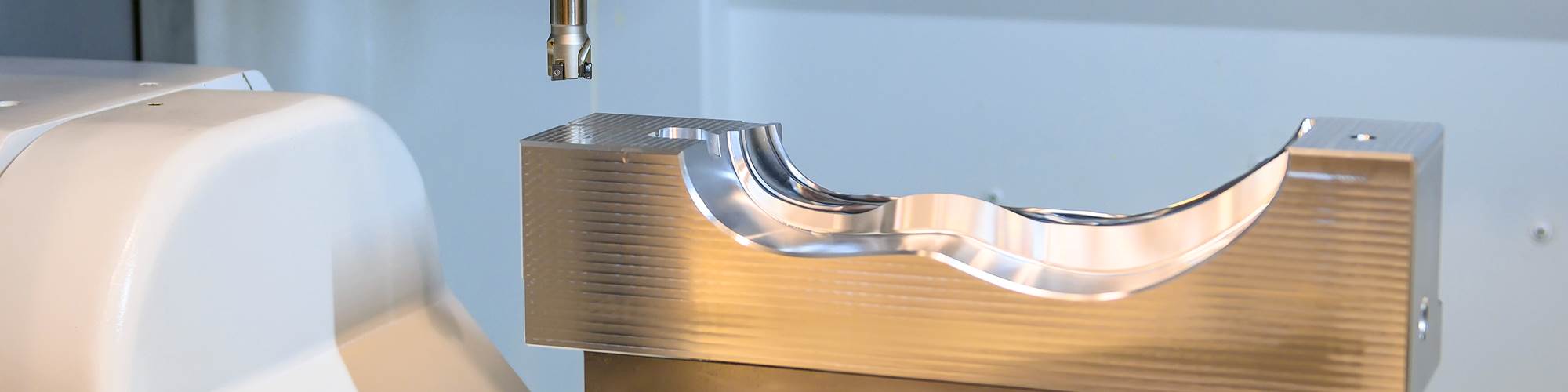

Aluminum selection is key as the right aluminum mold alloy will provide the required strength, anodizing response, weldability and machinability properties. Here, a five-axis machine cuts automotive tooling with solid ball end mills. Photo Credit: Getty Images

Aluminum alloys have been used in moldmaking for years because of their improved cycle times, yielding cost savings for both mold builders and molders. Here, we will focus on aluminum molds primarily used for plastic materials in both low-pressure (thermoforming) and high-pressure (injection molding) applications by reviewing the more common aluminum alloys used in moldmaking along with their strength, anodization, weldability, machinability, flatness and porosity advantages.

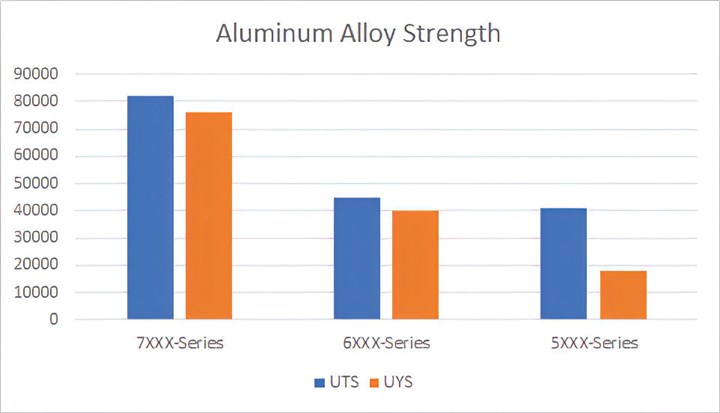

Aluminum companies developed the 7XXX series of high-strength mold alloys with properties that enable their use in applications that were only previously served by steel, including production injection molds and other high-pressure molds where mechanical strength and hardness are required. In addition, the 7XXX-series higher strength aluminum alloys offer better thermal conductivity than steel molds, improving cycle times.

Where strength and hardness are less of a concern, such as for prototype or low-pressure molds, other aluminum alloys like the 6XXX-, 5XXX- and 2XXX-series alloys are good alternatives. Aluminum alloys in the 6XXX and 5XXX series are typically less expensive than the 7XXX-series alloys and are readily available from metal distributors. However, 2XXX-series aluminum is becoming less available as mold builders have adopted 5XXX-series cast plates and block instead.

A point to note is that 7XXX-series and 6XXX-series aluminum alloys are heat treated and rolled, or rolled and forged aluminum alloys. These processes give 7XXX- and 6XXX-series aluminum alloys much higher mechanical properties than the 5XXX series. The 2XXX- and 5XXX-series aluminum alloys are typically cast plates and blocks, where strength comes from the alloying elements only. Each series has its advantages.

Distinct Advantages

Anodization creates hardness on the surface of an aluminum mold. Since the anodizing layer is porous (before sealing), various materials may be impregnated into the anodized layer to give the mold better performance with various plastic resins. Anodizing aluminum is a crucial process when surface hardness is required. While virtually all aluminum alloys can be anodized, the 5XXX series is particularly well adapted to this process.

Weldability of aluminum alloys is essential for molds, especially for prototyping, as it allows a shop to easily weld and re-machine a mold when necessary. For example, adding or repairing details, retexturing, etc. The 6XXX- and 5XXX-series aluminum alloys generally offer better weldability than 7XXX-series alloys.

As always, follow available or required standards when welding aluminum alloys — including the correct filler aluminum, pre-heating, cleaning and other prep work — for optimal results and to avoid defects such as cracking or porosity.

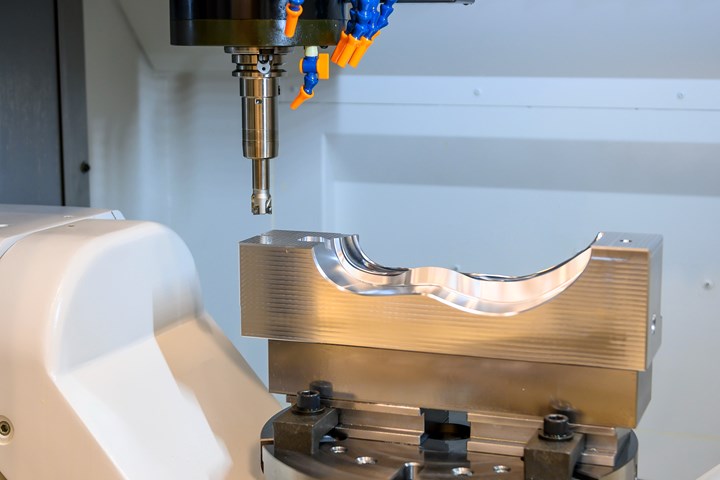

Compared with tool steel, aluminum offers outstanding machinability and ease-of-polishing characteristics. These properties reduce the lead times required to produce aluminum molds versus steel molds. Also, aluminum does not require a shop to send molds out for heat treatment or stress relief.

The rolling and forging processes used to manufacture the 6XXX- and 7XXX-series aluminum alloys result in high mechanical properties and contribute to residual internal stress, which is revealed during the machining process as movement or instability of the machined part. Shops must consider internal stress during the machining process to avoid producing molds that are out-of-tolerance or out-of-flat.

The 5XXX series of aluminum (aluminum cast plate or block) has virtually no internal stress. As a result, you can machine it much faster than other aluminum alloys. Also, this series remains dimensionally stable and flat during and after machining, often holding very tight tolerances.

Anodizing aluminum is a crucial process when surface hardness is required. While virtually all aluminum alloys can be anodized, the 5XXX series is particularly well adapted to this process.

Assured Quality

The quality of the mill or cast house producing the aluminum alloy determines the potential to eliminate porosity and inclusions that cause defects in aluminum plates or blocks. These defects may be attributed to the level of moisture or hydrogen present when the aluminum is produced. In addition, the source or percentage of recycled content used when making aluminum also plays a role in porosity or inclusion defects.

5XXX-series aluminum alloys perform well for prototype injection and thermoforming molds and are easy to machine and highly stable. Photo Credit: Getty Images

Aluminum mill producers that use and maintain the best degassing and filtering systems with controlled processes will always produce high-quality aluminum. In addition, the level of primary smelted aluminum versus recycled aluminum may also indicate quality.

Forged and rolled aluminum blocks — such as 7XXX-series mold blocks — should be virtually free of porosity due to the forging process. Minimal risk of porosity, depending on the mill producer, should also be offered by 6XXX-series rolled aluminum. Cast plate and block from the 5XXX series produced from high-quality DC cast ingots will also exhibit virtually no porosity.

Selecting an appropriate aluminum alloy for your mold application is often based on the molding process. For the most common and available aluminum mold alloys, consider the tradeoffs between the hardness and longevity of rolled and forged 7XXX-series aluminum and the excellent machinability and dimensional stability of 5XXX-series cast aluminum plate and block.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Addressing Aluminum Tooling Objections

Mold builder shares the technical and financial advantages it experiences using aluminum tooling.

Read MoreHigh-Performance Alloy Increases Performance Capability of Aluminum Molds

DRS Industrial’s use of high-performance aluminum alloys helps it build better molds faster and at a lower cost, improving molder productivity.

Read MoreThe Realities of Aluminum Tooling

Using aluminum tooling instead of traditional tools steels reduces cycle time and costs, but requires up-front, open communications between moldmaker, molder, material supplier and hot runner manifold supplier.

Read More