All-Electric Injection Molding Machines Exhibit Application Versatility

NPE2024: Engel offers attendees seven different exhibits featuring its selection of injection molding machines that address various parts of industry.

Engel invites customers to visit its exhibits at NPE2024 where the company addresses challenges faced by plastic processors across automotive, teletronics, technical molding, packaging and medical sectors. Each exhibit features one of Engel’s injection molding machines — all-electric, servo-hydraulic and two-platen systems — available to the North American market.

Engel additionally highlights its training programs and digital automation solutions — designed to overcome challenges introduced by the industry’s shortage of skilled labor — as well as its commitment to sustainability and a circular plastics economy.

Engel’s seven solution showcases are detailed below:

1. E-Mac Slim Edition

Engel’s all-electric E-mac is available in slim execution, providing a compact footprint for utilizing production space. Engel says that this model saves up to 16% in overall machine width. The E-mac 1565/310 is producing a technical molding part, a bottle tray, on a single cavity mold supplied by its partner, Haidlmair.

Despite the reduction in footprint, the mold space reportedly remains unchanged, providing enough room for large molds. Another aspect of this exhibit is that the tray is produced using regrind instead of repelletized material. Engel claims that a recycling package consisting of a highly abrasion and corrosion-resistant screw and a melt filter ensures consistent high process and part quality.

2. E-Speed 610/90

The Engel E-speed 610/90 is an injection molding machine designed for high-speed and high-performance production of packaging applications in the plastics industry. Its hybrid drive concept enables extreme injection pressure and speed at short injection strokes, which Engel maintains enables it to be used for applications with high demands in injection performance. This machine features a 4+4 cavity, high-speed family stack mold designed for tamper-evident food containers and lids with in-mold labeling (IML) and two different shot sizes.

The asynchronous mold carrier system, along with an integrated water manifold, enables simultaneous molding of both containers and lids. According to Engel, this system enhances productivity and streamlines the manufacturing process. The company’s mold partner, Top Grade Molds, also supplies its modular mold change system, designed to enable swift product changeovers. Automation is provided by Campetella, vision inspection system by Mevisco, labels by MCC Verstraete, stack mold carrier system by Nexteco, material provided by Washington Penn and auxiliary equipment by Frigel.

3. Victory 330/85

Engel demonstrates quick mold changes (QMC) on the hydraulic Victory 330/85 with a clamping force of 800 kN. Roembke Mfg. & Design Inc. provides this cell with the two molds for the application: salad tongs and a fruit bowl. The mechanical quick clamping system QMC from Stäubli is used for QMCs. Mold identification is carried out by means of RFID. The material used for this exhibit is HDPE, provided by Shell.

The iQ weight control machine software automatically adjusts the process parameters to batch fluctuations and changes in ambient conditions. This not only improves part quality during ongoing production, says the company, but also helps customers get parts faster after a mold change. An Engel Viper 12 linear robot removes the parts and places them on a conveyor belt. The end-of-arm tooling is also identified using RFID and exchanged with a quick coupling.

4. E-Motion 440H/160TWP Combi M

This compact injection molding machine with a horizontal rotary table is designed to boost shopfloor productivity. With a minimal footprint, two-component diagnostics cartridges are produced in cleanroom conditions on an all-electric E-motion injection molding machine 440H/160TWP combi M. This exhibit is an example of a customized, fully integrated production cell designed for minimal space requirements. The dual face mold, with 32 cavities each, come from Hack Formenbau.

In the Combi M design, the indexing table divides the injection molding machine’s mold closing area in the center to operate two mold faces in parallel. Engel maintains that this makes Combi M technology useful for integrating two-component injection molding and doubling the output. One injection unit is fitted on the stationary platen and the second is on the moving platen.

Two robots work in parallel to manufacture diagnostic cartridges. An Engel Viper 20 linear robot removes the two-component parts and deposits them in trays. Finally, an Engel E-pic pick-and-place robot covers the fully populated trays with an intermediate layer to stack them in boxes and then discharge them via a tray server, which is also integrated.

5. E-Motion 50/30 TL

With a 32-cavity precision mold and a micro injection unit, the all-electric, tie-bar-less E-motion 50/30 TL injection molding machine produces silicone valves with a part weight of 0.001g. The E-motion TL is designed for applications with high demands in precision on both the injection and clamping sides. In addition, a Viper 12 linear robot by Engel, in combination with an optical testing unit by ACH Solution, enables precise handling and control of the micro components. Engel’s smart software solution, iQ weight control, plays a key role in the production process — according to the company, the self-optimizing program ensures consistent shot weights despite viscosity differences of the two-component liquid silicone rubber (LSR) material from Wacker.

6. Duo 5160/770 WP Tech US

Engel runs a servo-hydraulic, two-platen Duo 5160/770 WP Tech US machine showcasing the production and decoration of components with high surface quality. Engel claims that the large mold area, equipped with a sliding table mold provided by Schöfer, offers possibilities for automation and technologies. The entire production operation is done with one machine and in one cycle using the two Engel application technologies, Foilmelt and Clearmelt, which the company says results in an efficient process for producing an automotive front panel.

This exhibit endeavors to address current trends in the automotive industry. It combines bio-renewable and translucent polypropylene from SABIC with polyurethane from Ruehl, which according to Engel, results in cost, weight and sustainability advantages. Additionally, an in-mold decorating (IMD) film from Kurz, simultaneously provides design and adhesion between the material partners, making surface treatment unnecessary. Furthermore, Engel introduces Cannon as an additional partner for dosing units.

This process is designed to merge decoration and scratch-resistant surface creation through IMD coupled with a polyurethane (PUR) coating. The part is ready for electromagnetic transparency, near-field screening with RADAR or LiDAR systems and option to integrate defrosting or capacitive films for additional features. It is a fully integrated production cell with Easix automation, PUR dosing and a temperature control unit.

7. T-Win 750/7800

Wintec, a member of the Engel Group, showcases a T-win 750/7800 (830 U.S. tons), which is uses to produces garage floor tiles molded from 100% recycled ocean waste. An integrated Engel Viper 40 linear robot completes the part takeout.

The servo-hydraulic Wintec T-win is equipped with an electric screw drive for parallel movements and energy efficiency. Since its release, Engel claims, the machine has been used across the market, particularly in technical and automotive applications. The company maintains that the T-win offers reliable performance, shot consistency and energy efficiency at a compact footprint.

IQ weight control is meant to demonstrate how a software can enhance the profitability of using recycled materials. By ensuring consistent quality and minimizing rejects, iQ weight control dynamically adjusts the injection profile within each cycle to maintain a constant fill.

Wintec’s customer, CH3 Solutions, supplies the mold for this cell. The raw material is provided by its partner, Atando Cabos. ExxonMobil provides material and additives for processing and part properties.

Related Content

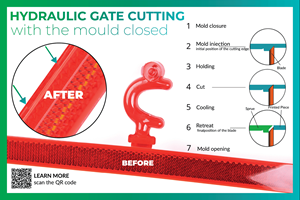

Hydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

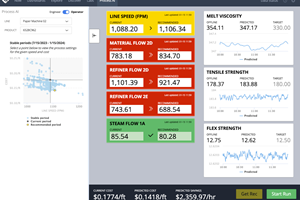

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreUse AI, Machine Learning to Take Variability Out of Manufacturing

Variability has always created insurmountable challenges for manufacturers. However, in the last decade, impact has been more painful due to a lack of experienced workforce. By leveraging technological advancements, particularly in AI, manufacturers can gain a transformative competitive advantage in both cost reduction and workforce development.

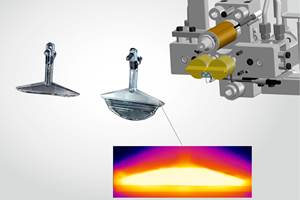

Read MoreLocalized Mold Temperature Control Reduces Knit Lines, Optimizes Melt Flow

NPE2024: Dynamic localized mold temperature control Heat-Inject Technology by Incoe Corp. demonstrates how the part surface quality and the filling of the cavity is optimized with relatively little effort using targeted heat pulses.

Read MoreRead Next

Training, New Technologies Target Mold Change Optimization

Engel is offering an array of technologies, as well as Basics, Advanced and Expert training courses to help molders optimize their mold-changing process.

Read MoreEngel, Top Grade Molds Present Conjection Process for Injection Molding

Coinjection process, which will be presented at Amerimold, reportedly uses more than 30% of recycled material and switches from recycled to virgin material close to the cavity, directly at the injection nozzle to ensure continued quality.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More