Process Monitoring, Cold Runner and Nozzles Bring Control, Industry 4.0 to the Mold

Ewikon touches on a few of its popular innovations previously highlighted at K 2019, including the HPS III-MV multi-tip nozzle, smart Control and Coolshot.

Hot runner solutions manufacturer Ewikon highlights a nozzle range for vertical multi-gating as well as solutions for process monitoring and cold runner solutions for the efficient processing of liquid silicone rubber (LSR).

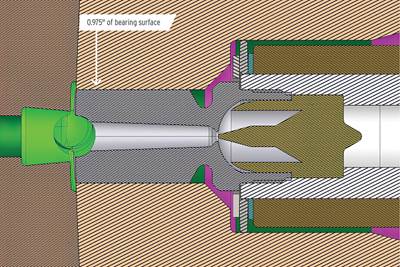

The HPS III-MV multi-tip nozzle for the vertical gating of parts is now available in a new, more powerful version. The nozzle features state-of-the-art hot runner technology with optimized temperature control — a coil heater integrated into the pressure tube provides stable heating and an even temperature profile. It is particularly suitable for the processing of technical resins with narrow processing windows, as well as fiber-reinforced materials, used for electronic, technical and automotive parts.

The multi-tip nozzle is available in two nozzle body diameters, which can be combined with several tip insert sizes for simultaneous gating of 2-6 parts, with pitch diameters from 10.5-25 mm. These options enable optimal adaption of the nozzle to different application requirements, shot weights and resins. The nozzle’s front installation option facilitates quick maintenance and is easily accessible for replacement or tip insert exchange once the cavity plate has been removed. In addition to the standard product, a high-performance hot sprue variety is also available.

Moreover, the HPSIII-MV nozzle has part of the melt distribution already integrated into the nozzle, maintaining the small and compact nature of the manifold. This feature reduces total flow path length and facilitates the processing of materials that are temperature sensitive and have short residence time, such as POM. These features also enable optimal direct gating of small or micro parts.

Ewikon’s smart Control is a process monitoring device for hot runner systems with Industry 4.0 capabilities. The compact process monitoring and diagnosis unit is an option available for new hot halves, which is delivered wired and mounted on the wiring box of the system. The smart Control monitors, analyzes and logs all relevant process and system parameters over the entire life cycle of the mold, thus giving injection molders more transparency during the production process. Data, including but not limited to nozzle and manifold temperatures, running times, downtimes and shot numbers are permanently collected and logged. Defined critical values can trigger a warning output signal when they are exceeded and, if required, can be reported by email. All data can be exported by using WLAN or Ethernet. Three digital inputs and two digital outputs enable the processing of additional digital signals

A browser-based user interface, developed by Ewikon, provides clear visualization of the data and is accessible by IP address from mobile devices or over the company network. Additionally, data can be transmitted directly to Ewikon for quick remote diagnosis on system errors, allowing for early initiation of specific maintenance activities and minimizing the downtime of the mold.

In addition to these innovations, Ewikon introduces the Coolshot high-performance cold runner system for the reliable and efficient processing of various types of LSR. The system features the company’s electric drive valve gate systems. An electric step motors achieves high-precision positioning of the valve pins in steps of 0.01 mm for fine-balancing of the cavity filling. The adjustment of the valve pin open position by controller is possible at any time without cycle interruption, which reduces time expenditure when it comes to system setup and readjustments during production. This is in contrast to conventional manual mechanical adjustment required at the mold. Coolshot enables permanent monitoring and automatic adjustment of the valve pin positions by use of encoders. A touch screen panel offers comfortable operation and features remote control access by using a tablet PC (iOS, Android, Windows) with VNC viewer.

The water-cooled cold runner nozzles are available with various tip versions depending on the LSR grade being run. The different tip options allow thermal separation to be tailored to the process, thereby achieving quick cycle times even for applications which require colder mold temperatures.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Hot Runner Truths, Myths and Overlooked Areas

Addressing hot runner benefits, improvements and everyday issues from the perspective of decades of experience with probably every brand on the market.

Read MoreValve Gate Nozzle Enhances Direct Side Gating Capabilities

NPE2024: Ewikon is introducing the pro Edge VG range which sets new benchmarks in terms of ease of maintenance, gate quality and flexible use.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More